DIY Paper Tape/Punch Card Maker and Reader

Introduction: DIY Paper Tape/Punch Card Maker and Reader

Paper tape and punch cards were used back in the 1950's and 60's (and even as late as the 1990s) as data storage for various computers and even CNC machines! To hand cut or to hand read the card would be terribly time-consuming so why not just make your own!

- Parallax Propeller Activity Board (or MCU of your choice)

- Silhouette Portrait

- Drill Press

- Nail/Hammer

For the Paper Tape/Punch Card reader head:

- Scrap Ribbon Cable

- 2x 1x10 male header

- 10x photoresistors

- 10x 3mm white LEDs

- Soldering Iron/Solder

- Wire Strippers

- 100 ohm resistor

For the Paper Tape:

- Old Folder (not manila or transparent)

Step 1: Create the LED Reader

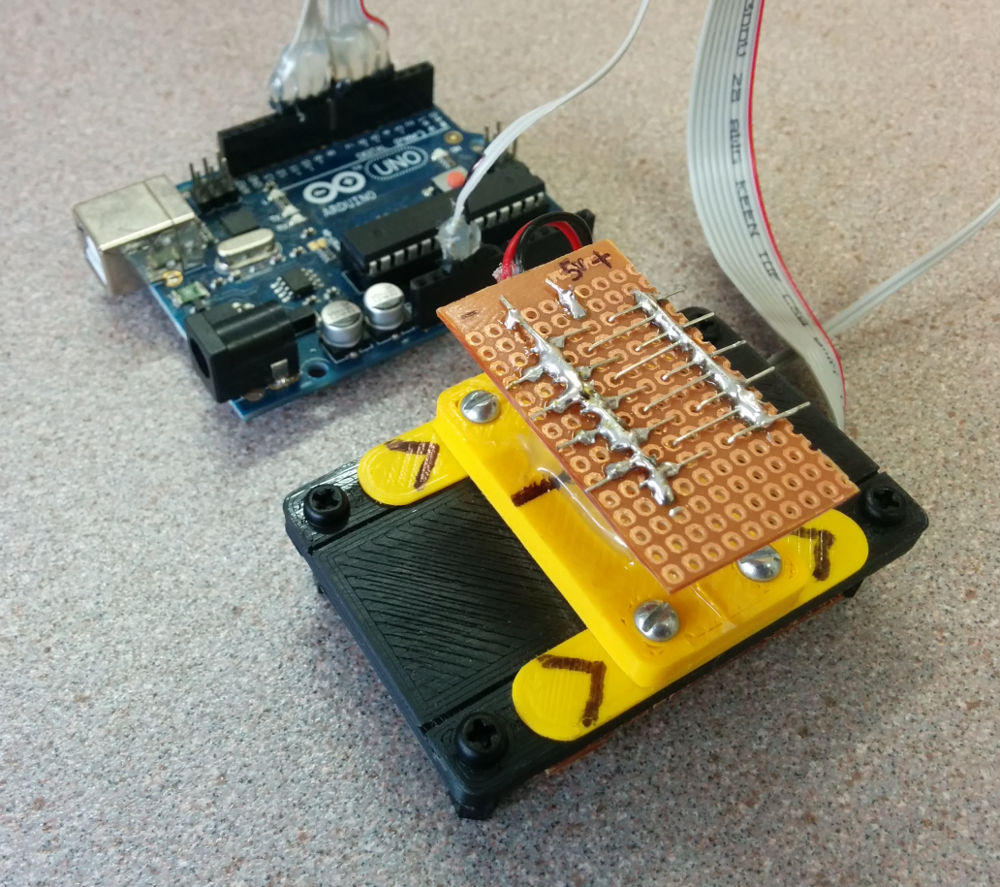

Solder the 10 photoresistors to a piece of perfboard. The perfboard we used consisted of 2x 2x20 columns with horizontal electrical connections. Solder the photoresistors between these two columns - though if you set up the electrical connections, you can use any kind of perfboard.

One one side, bend one lead of each photoresistor to connect to its neighbor and solder them together. Trim any extra pieces off. This side will be connected to Vcc (3.3V) eventually.

Step 2: Solder the LED Reader to a Header

Take a piece of ribbon cable with 10 lines and about 6-10" in length, and strip about 3mm on both ends and tin them. Solder these to a 1x10 pin male header.

The first 9 wires from the header should be soldered in order to the perfboard. Make sure to solder them on the side where the photoresistors are NOT connected to each other. And make sure the wires are coming out from below the perfboard, away from the photoresistors.

The last wire will provide power to the photoresistors. Solder this to the other side of the photoresistors, opposite of the wires you just soldered.

Step 3: Create the LED Bar

Using another piece of perfboard, place the LEDs in the same spacing as the cadmium cells. You want to make sure that the polarity of each LED is the same as the next. Using the same method as before, take the leads of the LEDs, bend them over to touch the lead of the LED next to them, and solder them together.

Do this for both sides. One side will connect to GND and one side will connected to 5V. Do not, however, test these lights without a current limiting resistor!

Take ribbon cable and solder one wire to one rail/side of the LED perf board, and solder another wire to the other side. On the end of this ribbon cable, solder a 1x2 pin male header.

Step 4: Set-up the Chassis for Paper Tape Reader

Look through your scrap wood! I found a black walnut piece that was roughly twice the height of the LEDs off of the board and wide enough for ~1.5cm clearance on either side of the perfboard.

Using a spare header, mark out where the leds are. This will serve as a template for where you need to drill the holes for the LEDs. Mark where you will need to drill on the wood.

Step 5: Drill the Holes for the Chassis

Use a tap (nail and hammer) to mark where your drill bit will drill through the piece of wood. This helps to keep the drill bit from drifting when you first start drilling.

Choose an appropriately sized drill bit which will allow the LED to fit snugly in.

Drill the holes all the way through the piece of wood.

Step 6: Cut the Piece of Wood in Half

Using a sturdy guide and your bandsaw, cut the piece of wood you just drilled into two halves (or slices). This will take a little bit of time depending on the type of wood you've chosen.

Once the two halves have been cut, sand to get rid of any large imperfections.

You can now testfit the LEDs into the holes you've just drilled. One half of the chassis is now complete!

Step 7: Set Up the Wood Piece for the Photoresistors

Using a table saw, carefully route a 1/16" slot into one side of the wooden board. This slot is where the paper tape goes through. We made this slot width 2.25" wide, but if you want to create wider paper tape, you are welcome to do so. The way our table saw blade cuts, we made it a ridged slot, but you are welcome to make it a flat surface.

Then, turn this board 90 degrees, and cut out a 1/16" slot for the photoresistors to fit in. The width of the slot will be the width of a photoresistor. You do not want too much play for the photoresistors to move, and you want to make sure the slot is cut where the holes are. This will keep the distance between LED and photoresistor short, to prevent light bleed from other LEDs!

In the last photo, you can see the slot and clamping to ensure that all of the pieces fit together.

Step 8: Create the Resistor Network

Take a 1x10 pin male header and solder 9 10k ohm resistors - one to each pin. Take the other lead of each resistor and bend it over to the next resistor. The last resistor is soldered to the 10th pin. This will eventually be connected to GND.

Step 9: Connect the LED Reader Portions on the Breadboard

The great thing about Parallax Propeller boards are that they have small breadboarding spots. Please refer to the diagram to see where the connections should go.

You will need wires to go from the various headers to the pins, and to the appropiate VCC/GND points. For the LED bar, you will need at least a 100ohm resistor to act as a current limiting resistor, otherwise at 5V, you WILL overdrive the LEDs and risk having to resolder them!

Step 10: Glue Up the Hardware!

This step can theoretically be done at the end after you've tested the code, but in case you'd like to be done with the hardware portion, here it is!

Glue up the two halves of the wooden reader. Remember to only put glue on the ends, and not inside the slot since the paper tape needs to go through that slot!

Once that has cured, take a look at the gap between the perfboard and your wooden reader when the photoresistors are seated in the slot. My perfboard and the wooden reader happened to be separated by the the height of a PCB. So I took small bits of a scrap pcb and using pro-bond, glued it to the ends of the perfboard.

Once that has cured, place glue on the little scrap pcbs and clamp that to the wooden reader. Make sure to not get any glue on the photoresistors lest you block light!

Your set up should roughly look like the one in the last photo for this step.

Step 11: Program the Propeller

Now that you have the hardware set up, program the Propeller's eeprom with the following code. What this does is show you what letters your punch card/paper tape represent - so you know what the message is! I will show what you will see at the end!

Code: http://pastebin.com/D9ZdHQsg

Step 12: Creating Your Paper Tape!

We are finally to the point where we can create our paper tape!

Take an older folder you may have lying around and have no use for. Cut it so that it's a useable rectangle/square. Affix it to the Silhouette cutting backer, and load into the Silhouette Portrait with the top right button.

We threw a quick program together (instead of laying the message out by hand in a graphics editor) which would allow you to write whatever message we wanted. This paper tape reader uses ASCII bit representation, so it can support odd symbols as well as your typical A,B,C.

With the program, we had it save out to a bmp which we could then upload to Silhouette Studio.

Note, when you make your graphic, make sure the index pulse (a pulse that is on all of the time to let the system know when to read the line), consists of smaller holes than what your data is represented by. This helps prevent false-positives.

Step 13: Print the Paper Tape/punch Card

Using Silhouette Studio, set your graphic up for printing. I had to resize the document in Silhouette Studio to a height of 2.037", and an overall border that had a 2.117" height. This will be different depending on the width of your board and on the size of your holes and how they match the holes you've drilled.

Easiest way I did this was by printing out different tape sizes and looking to see which ones matched the best. This portion may be the most time intensive but is the most important for ensuring the data you're sending to the serial terminal is correctly read.

Set the Silhouette cutting setting to cut cardstock with a speed of 4, thickness of 33, and allow for double cutting. Now, send to printer and wait!

You will see the following! (note picture 3)

Step 14: Clean Up the Paper Tape

Clean up time! Take your cut piece off of the backing and start cleaning out the holes! Ideally, most of them should come out fairly easily, but there may be occasionally "hanging chads" that you need to get rid of. I used a small screwdriver to help in the process.

Confetti for everyone! Data for me :).

Step 15: Test, Run, and Use!

Now that you have everything wired up, you have the reader ready - turn on your Parallax Propeller board. The LEDs should all light up. Remember that the led that is farther from the others should be matched with the index pulse. If you are seeing odd messages, make sure that your header from the photoresistors is plugged in, in the correct direction.

In any case, enable the serial terminal and run the card through!

Looks like our message for this card is....

Hello, World! Testing 12345. ASCII

Now, you can create longer messages by making actual tape or combining multiple punch cards, or keep it nice and short and treat this reader like a card reader! Enjoy!

Recommendations

Books and Bookshelves Contest

Make it Resilient

Engineering in the Kitchen - Autodesk Design & Make - Student Contest

Solving yesterday's problems today

- Arcade Games

- LittleGP-30

- Telefunken Rollkugel

- Using the reader

- Building the reader

- Accessories

- Other Projects

© 1999-2023 Jürgen Müller [email protected]

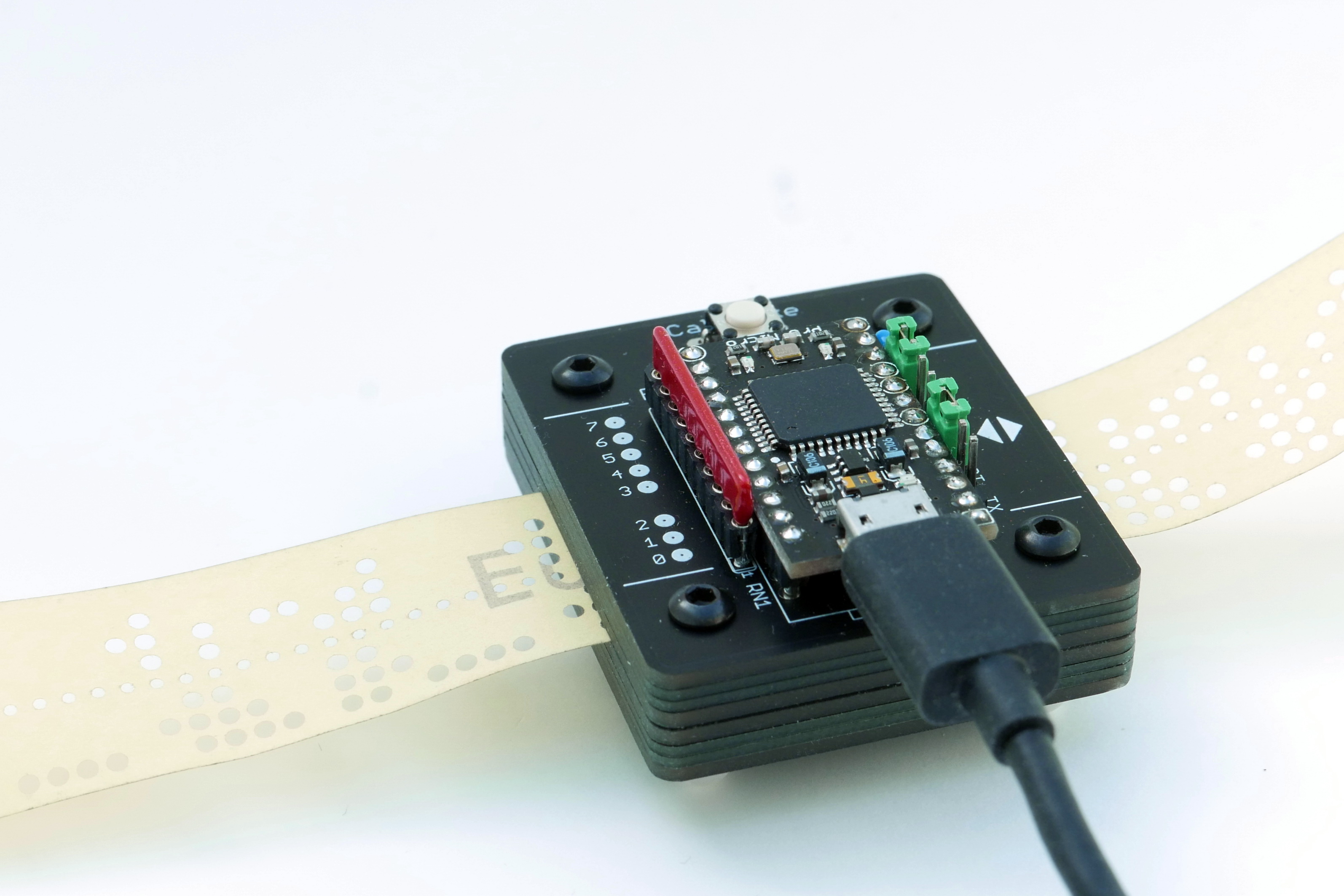

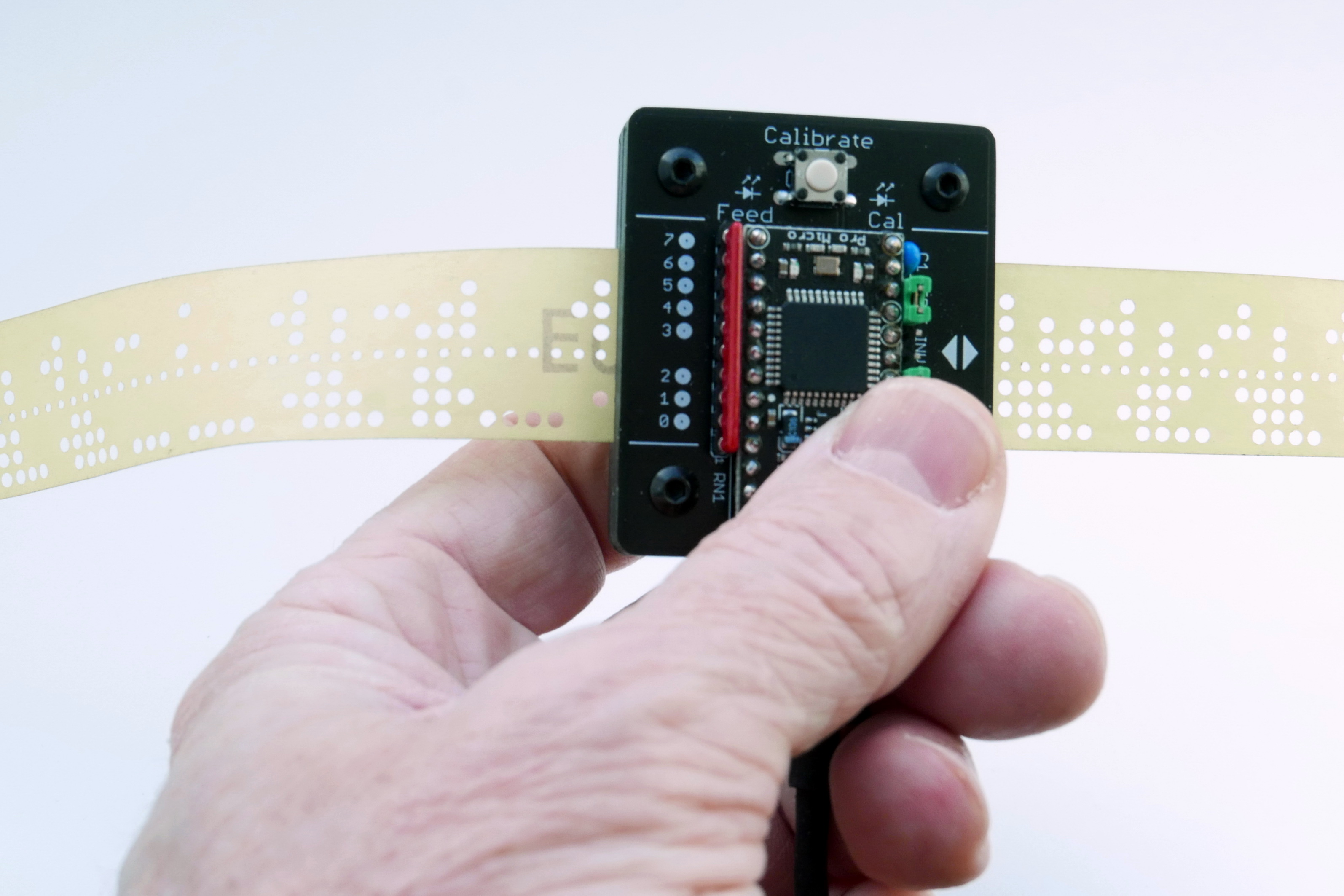

This little manual paper tape reader is easy to build and operate. It connects to any modern computer via USB, and performs well with all kinds of 5 to 8 bit paper tape, including translucent paper materials. To compensate for sensor tolerances and adjust to different paper types, it can automatically calibrate its optical sensors.

The paper tape reader is controlled by an Arduino Pro Micro. Punched holes are detected optically, via analog inputs to the Arduino and automatic thresholding in software.

Optical readers for punched paper tape have been used since the 1940s; the one developed in 1942 for the British Colossus deciphering machine was probably among the earliest. Non-motorized optical readers, where the tape is pulled through by hand, became popular with early computer amateurs in the 1970s. Oliver Audio Engineering launched the OP80A as a kit or complete unit in 1976; a replica is still commercially available today. And to this day, amateurs interested in the old paper tape format occasionally build their own optical readers.

This project takes a slightly different approach than most builds. While I also use LED & phototransistor pairs to detect the presence of holes or paper, and use the feed (sprocket) hole to trigger a read cycle, this reader does not distinguish “zero” from “one” via hardware comparators or Schmitt triggers. Instead, the on-board microcontroller (a Sparkfun/Arduino Pro Micro) reads the phototransistor currents via its analog inputs. This way it can adjust the detection thresholds in software, to compensate for tolerances between the phototransistors and to adjust to different paper materials.

The sales pitch

Easy to use. Just connect it to any modern computer (Windows 10, Mac OS, Linux) via USB, open a terminal program or copy from the serial device to a file, pull through some paper tape, and you are in business. You can calibrate the sensors to difficult-to-read, translucent tape by pushing a button and feeding about 30 cm of test tape. But one calibration handles a wide range of paper types, and stays resident in EEPROM memory, so you don’t have to calibrate much at all.

Easy to build. Only through-hole electronic components are required. Most mechanical parts consist of pre-fabricated circuit board material – just add four screws and some adhesive tape (which is used as a spacer to guide the paper tape). No hand-selected resistor values to get the sensor switching thresholds just right, since all sensors are calibrated in software. The microcontroller is programmed via USB and the standard Arduino environment.

Works pretty well. Due to the analog sensing and software calibration, the reader handles a wide variety of tape materials robustly, including highly translucent white or yellow paper. It is insensitive to environmental light since the tape and sensors are fully encapsulated. While it’s not the fastest reader around, reading speed is probably limited by how fast you can pull the tape through without damaging it: Reading at 1.2 meter/second (500 characters per second) should not be a problem.

New Handy accessories. Several builders have designed clever accessories for the paper tape reader. Using mostly 3D-printed parts, they make tape handling more convenient. Take a look at the Accessories page!

Operate the reader handheld or mounted to a base plate. Tape is pulled through manually, at up to 1 meter/second feed rate.

The two main modules are the phototransistor detector (left) and the LED illuminator (right). The Arduino sits on top of the detector module. Only two power connections go to the illuminator.

All chassis parts are made from PCB material: Circuit boards for phototransistors and LEDs, masks to precisely define the illumination and detection apertures, and light-tight spacers.

- Knowledge Base

- Buyer’s Guides

- White Papers

- RAID Calculator

What is Punched Paper Tape, and How to Read It

The strange link between the NSA, Queen Victoria, and a mechanical orchestra

To most people who can even remember what punched paper tape is, it’ll seem like a relic of yesteryear. But as we’ll see, that’s not strictly the case. What is punched paper tape? It is a very old way to encode programs and data on long strips of paper so that they could be stored, transported, and read back into computers. So why are we still talking about it today?

Where Did Punched Paper Tapes Come From?

Physically reading the tape.

- Booting Computers From Punched Paper Tape

The Coding Used on the Tape

The original bit bucket.

- What Has This Got to Do With Cyber Security

What is Punched Paper Tape?

Punched paper tape was used as a computer storage media from the 1950s onward, probably hitting its heyday in the first half of the 1970s. It used long reels of paper tape that had holes punched in them, typically with five or eight holes across the width of the strip. They were about one inch wide (25mm). Each line of holes represented a character or operational code (op-code) in some form of encoding, usually in binary. When the tape was fed through a reader the information on the tape was interpreted by the computer and reassembled into the program or data.

Of course, long strips of paper are fragile and must be kept dry. But reels of paper tape are cheap to produce, light, easy to transport, and not affected by magnetism. Shorter runs of paper tape were sometimes used in a concertina fashion, with lengths of the paper tape folded back over itself, repeatedly. The stack of punched paper was fed through the tape reader and hand-folded back into a neat stack.

The paper tapes could be toughened to a degree, but that led to a dilemma. The tougher you make the paper the more you reduce its flexibility. Some paper tapes I’ve seen employed quite a heavyweight paper with a waxy finish in an effort to make them more robust and at least a little waterproof. Some of the more expensive paper tapes were actually a sandwich of paper, a stretched polyester film, and paper.

Machines being fed information from perforated paper or card were in use as long ago as the early 1700s when punched cards were used to control automated looms. The punched cards were joined together in a long flexible belt that was fed through the loom control machinery to dictate the pattern that was woven. Effectively, they behaved like a clunky punched paper tape. Genuine punched paper tape was introduced In 1725.

In the late 19th and early 20th centuries waxed paper rolls were used in pianola or self-playing pianos. Self-playing instruments didn’t stop with pianos, however. It was possible, if you were rich enough, to have a machine called an orchestrion built for you. There are very few of these left in the world, and even fewer still in operation.

Many years ago I was lucky enough to see one working (sadly it is now in need of restoration) in Kinloch Castle on the Isle of Rum, off the West coast of Scotland. It was ordered by Queen Victoria, but she died in 1901 before it was completed. It was bought by a wealthy baronet who had it installed in his Castle. On his private island. I did say rich, right?

The music was encoded onto large paper rolls with a maximum of 108 holes per line of data. The orchestrion “read” the punched paper pneumatically . There were 108 pipes behind the roll, one for each possible hole. They were constantly trying to suck air into the machine.

If the paper had no hole in a certain position, that pipe couldn’t suck in air. If there was a hole, air was drawn in through the pipe which inflated a small bellows. This triggered a series of actuators that worked upon the various brass, keyboard, woodwind, and percussion instruments. Some holes represented musical notes, some holes represented registers and keys, and other holes represented the different instruments. Hearing it play Wagner’s Ride of the Valkyries whilst wondering if it was going to shake itself to bits was quite an experience.

Back in the world of IT, punched tape readers have used a variety of techniques through the decades to read the data from the tapes. The earliest schemes were electro-mechanical. Levers or rods were either permitted to move or prevented from moving depending on the presence or absence of a hole. Later models used electrical contacts that would complete a circuit only when a hole in the tape was beneath the contact.

Later models used photo-electrical assemblies. Light is shone onto one side of the paper tape and sensors on the other side detect the light that comes through the perforations. Timing was everything, of course. Along with the data holes, the paper tape has another set of holes called sprocket holes.

A sprocket hole is present on every line of the tape, and are much smaller than the data holes. These sprocket holes mesh with a sharply cogged wheel. A sprocket wheel can be active and help propel the tape through the sensor, or it can be passive in which case it is turned by the paper moving over it. The sprocket holes were off-center on the paper tape. On a five-hole tape, the sprocket holes are between data holes two and three, and on an eight-hole tape, they are between data holes three and four.

This helps you to determine which way up the paper tape is. Usually, the manufacturer would print the word “top” every 20 inches or so (0.5 meters) along the length of the tape. Printed arrows indicated the required direction of travel through the reader. But not always. Sometimes they were completely blank. These would get scribbled on quickly to avoid mistakes, which was especially easy with folded concertina tapes that weren’t on spools.

Each sprocket hole lined up exactly with the center of the data holes on each line. When the sprocket wheel moved forward one “click” the system knew it was time to take another reading. It wasn’t “looking out for flashes” and trying to capture them, it knew when to take a reading. This meant that the tape could move through the read assembly at almost any speed and the readings would be taken at the correct instant for each line.

Booting Computers from Punched Paper Tape

As well as holding programs and tape, many of the mainframe and minicomputers of the day were booted from tape. Some of them, like the DEC PDP/11 range, didn’t even know they were a computer when they were power cycled. For all it knew, it was a toaster.

By toggling switches on the front panel you could set up instruction values and memory locations, op-code by op-code, punching them into memory one at a time. Once your short bootstrap program was entered into RAM like this, you could run it. It would allow you to read a tape. By that I mean it would read one particular tape, called the absolute loader . When the absolute loader tape was loaded you could use it to load other tapes.

By the end of that process, if all was, well… it knew it was a PDP/11.

Because of the different architectures and word sizes in use, the codes used to punch data onto the tapes varied from computer manufacturer to manufacturer. Many schemes used one data hole per line as a parity check bit. On an eight-hole tape, you’d have seven holes left for encoding data and four holes on a five-hole tape.

With a parity bit, on an eight-hole tape, you have seven bits to encode with. 1111111 in binary is 127 in decimal, meaning you have 128 different codes that can be punched into the tape—if you take 0000000 as the first code. These codes can be assigned to binary data values, op-codes, or they could be assigned to values representing letters.

Rarely would the computers of this period use plain ASCII, even though that standard had been available from 1967. It wasn’t even possible to encode ASCII on five-hole tapes. These were restricted to a very limited character set, and capital letters only. Even with an eight-hole tape, each manufacturer would add their own twist to the encoding, so pure ASCII was a scarcity.

To give you an idea of the code on the tape, if they were using ASCII, this is what “PAPER” would look like, using the seven data bits of an eight-hole tape.

Of course, to keep you on your toes, some systems reversed the bit order. In such a scheme, hole seven held bit one . Other encoding variants used Gray Code. This is written in binary, but only one bit changes at a time. This principle is used to aid error detection.

Some tape readers were standalone devices, connected to the main computer by a harness of cabling. These readers were often used with concertina or fan-folded paper tape. It was rare to see them used with spools of paper tape. Although you could, of course, unspool the paper tape loosely into a container like a cardboard box let the reader whip through the length of the tape, and let it stream out the other side into another handy box.

Computer cabinets that incorporated paper tape readers had a feed spool and a take-up spool. The take-up spools were powered and pulled the tape through the tape reader head, across a platen that held the photo-electric assembly and the sprocket wheel.

With each revolution of the take-up spool more tape was transferred to it. So the diameter of the tape on the wheel grew progressively larger through the reading process. The amount of tape pulled through for one revolution of the take-up spool was much larger at the end of the run than it was at the beginning. So the paper tape was being pulled through at a steadily increasing rate.

This is where the sprocket wheel came into its own. Regardless of the speed of the tape, every time the sprocket wheel moved forward one click the system knew it was time to take a reading, making it a self-clocking system.

That didn’t stop some computer manufacturers going to great lengths to try to maintain a fast but constant transfer rate from one spool to the other. As the diameter of the tape on the take-up spool increased, the revolution speed of that spool was slowed down. The feed spool was also driven and that sped up as the take-up spool slowed down. Even the sprocket wheel was driven.

It never worked properly. If it got even slightly out of synchronization, different elements of the feed chain would be moving at different speeds and the paper tape was subjected to strains it couldn’t cope with. After all, it was only paper. It frequently snapped, or the sprocket wheel acted like a mini table-saw and cut the tape into two long strips. One of which had three holes in it and the other had five holes in it.

The workaround was to take off the take-up spool and let the tape fly out of the read assembly. A nimble young apprentice (yours truly) stood armed with a clean plastic dustbin trying to catch the cascading tape in it. He was then given the empty feed spool so that he could hand-wind the tape back onto it.

We had table-top splicing kits with integral punches to repair broken tapes. It was entirely possible, but tedious. Sellotape saved the day on more than one occasion.

What Has This Got to Do With Cyber Security?

For some, this is a trip down memory lane. For others, punched paper tapes are still a part of their day job. Specifically—and no doubt surprisingly—in the National Security Agency (NSA), one of the intelligence agencies of the US Department of Defense.

The NSA is phasing out paper tapes and will do so within 12 months. The final production run is going to happen this year. At their peak use, the NSA was creating millions of paper tapes per year. They were having it delivered in 5000 feet rolls—that’s almost a mile (1.5 kilometers)!

The tapes the NSA creates contain cryptographic keys or seed values for cryptography algorithms. These were distributed to whoever required them—such as the UK’s General Communications Headquarters (GCHQ)—in tamper-proof plastic containers. You have to destroy the container to remove the tape so it is obvious if the key or seed value is compromised.

Needless to say, the demise of paper tapes as a core element in the distribution and management of their cryptographic keys will see the NSA adopting digital methods.

It’s remarkable to think that some of the closest guarded secrets in the modern world are still relying on a medium that saw its birth in weaving looms in the 18th century, almost 300 years ago.

RELATED ARTICLES MORE FROM AUTHOR

Securing Kuburnetes with StackRox

ExpressVPN Review: How Does It Perform (and How to Install) on Ubuntu?

What is Whistleblowing, and How to Remain Anonymous

Latest posts.

How to Delete a Folder From File Station on a QNAP NAS

Diskashur M2 Secure SSD Review: IP68, FIPS 140-2 Level 3 (soon) and a Good...

Seagate IronWolf 510 Review: A Long-lived NVMe Caching SSD Specifically for NAS

- Sponsorship

- Terms of Use

- Privacy Policy

- My PDP-11/44

- Trying to setup an ALL07

- MicroVAX CPU parity error

- Defective DEC RD53 disk drives

- My first PDP-8a

- VAX 11/750: The Resurrection of a Comet

- DECbox and BlinkenBone on VCFE 14

- The PDP-10 KI10 console panel

- Getting RSX11M+ running on SIMH

- Love affair with the DEC PC05 papertape device

- PDP-11/70 Panel Research

- PUniBone PDP-11 processor test bed

DEC PC05 paper tape reader/puncher

The PC05 is the standard device on DEC PDP-11's to read or punch paper tapes . It was used in the 1970's, like most DEC devices of this aera it is mounted into 19" racks.

It needs the PC11 papertape controller (DEC module M7810), which is only available for UNIBUS. QBUS PDP-11's can not use the PC05, they have to use reader/punchers with a serial interface.

In contrast to ASR33 teletypes, it can read at 300 characters per second. An ASR33 can read 10 chars/second, so DEC called the PC05 "High speed". Is this fast? In 2015 there is just one device famous for an even lower transmission speed: the space probe "New Horizons" transmits data at 1 kBit/sec. This is 125 bytes per second ... from the distance of Pluto. That's one for Randall: "WHAT IF they'd use a 3 billion miles long paper tape instead of radio?"

Also in contrast to ASR33, it PC05 processes paper tape in a "fan fold" manner. DEC folded the paper tape strips, so after read-in they must not be spooled back. Instead after reading a tape the folded paper tape could immediately stored away or put into the reader again. Storage of folded strips was also more handy.

Basic documentation for the PC05 is on bitsavers , but not for all variants. The XXDP diagnostic for PC11/PC05 is "ZPCA".

The PC05 was only made for 115 VAC line voltage.

For the European market, DEC mounted 220V/110V step down transformers to the back door of their rack cabinets.

Usage on other PDP's

The DEC "High speed Papertape Reader and Punch" was used with little modifications on severals DEC computer lines: in PDP-8 (as PC04), in PDP-10 (as PTR/PTP10), in the PDP-11 and PDP-15 as PC05. It was constructed in 1969 (according to the earliest note on the schematics), and several thousands must have been build (check out the serial number on the identification plate shown below). In the 1960's there was also an older PC02.

The construction of the core device was identically for all PDP's, only backplane wiring and module usage differed.

The host PDP can be recognized at the identification plate. The plate contains also the serial number for the host controller, which is "PC15" for PDP-15 in this case.

Even big machines like the PDP-10 with lot of tape and disk drives were equipped with the slow paper tape reader:

One main use for paper tape always was running the MAINDEC diagnostics, which were delivered on paper tape sorted into blue plastic trays (see the one glued onto the PDP-10 in the picture above).

Know your PC05

The reader and the puncher unit inside the PC05 are two separate devices. They only share the chassis, the flip chip backplane and the power supply.

1 = Power supply. 2 = flip chip wire wrap backplane with electronic modules. There's no interconnection between reader and puncher logic. 3 = reader stepper motor with hold resistors (wasting energy as if it were free). 4 = reader head with lamp, feed wheel, tape depressor and photo transistors to read the paper holes.

5 = puncher, made by Roytron. It operates like an electrical typewriter: electric signals drive solenoids, solenoids move small control metal strips, these lock the actual punchers with a rotating wheel, and the punchers are pushed upward through the paper for one rotational period.

6 = waste container for punched out "chad". 7 = paper tape to be punched. 8 = electronic switch for puncher motor ("triac assy"), invisible here. 9 = reader and punch 40 pin flat cables to UNIBUS PC11 controller.

Logic modules

The PC05 logic consists of these modules (varies with version of PC05):

M715: "Reader Timing". Generates signals for the stepper motor.

M705/7050: "Reader Control", contains data latch and state machine for the reader.

M710: "Punch Control", contains data latch and state machine for the puncher.

3x M044: power driver for the solenoids in the Roytron puncher. Total of 12 channels, but only 10 are used (the feed hole is driven by two channels)

4x M040: "Solenoid driver", power drivers for the stepper motor. Four phases are driven by two channels each.

G918: Photo amplifier, generates logic signals from the photo transistor array in the reader.

K303: Timeout unit, to be used for puncher motor activation. Only used on older M710.

paper tape reader, BTR, DNC systems & repair services for most tape readers & tape punches. CNC machine paper tape reader, BTR ( tape reader replacement ), & DNC ( direct numerical control ) systems.

Search code, repositories, users, issues, pull requests...

Provide feedback.

We read every piece of feedback, and take your input very seriously.

Saved searches

Use saved searches to filter your results more quickly.

To see all available qualifiers, see our documentation .

- Notifications

Punched paper tape reader - 3D model and source code

gav-/PaperTapeReader

Folders and files, repository files navigation, papertapereader.

Punched paper tape reader - 3D model and source code.

This is a punched paper tape reader that allows tape to be pulled through by hand, using the tape's feed holes as a clock/trigger. The tape can be pulled at any speed as long as it is not allowed to slacken.

These are some extra notes off the top of my head:

In the 3D model, the LED emitter hole for the paper tape feed hole is smaller than the rest. This turned out to be a mistake, and the emitter for that hole had to brightened to compensate. It is recommended to modify the "feedHoleRadius" in model/PaperTapeReader.scad to the same as "dataHoleRadius", and export a new .stl from OpenSCAD.

Setting the correct emitter brightness is important. Ideally it is as bright as possible where the paper still satisfactorily blocks the light where no holes are punched. Test with various resistor values and your own paper tape to get it right.

I haven't added a schematic, but the wiring should be simple, basically just power the emitters from a 5V out (and an appropriate resistor), and tie the phototransistors to pins 4,5,6,7,8,9,10,11. I used external pull-up resistors on the phototransistors, this was a waste of time as the Arduino Uno has internal pull-ups that can be enabled. The setup() function in src/TapeReader/TapeReader.ino should be changed to enable internal pull-ups.

- OpenSCAD 43.4%

home about gallery cellar workshop soapbox gadgets avstuff computing radcom rescues diy vptr miy

Virtual Paper Tape Reader with added punch!

see copyright notice . Page created 1-Dec-2020 updated 7-Mar-2022. Use the button groups above to navigate quickly around the site.

I'm eternally grateful to Brentwood School, and Mid-Essex Technical College (METC, as was) in Chelmsford, for giving us school-kids access to the latter's NCR-Elliott 4120 computer in the late 1960s and early 70s. For the most part, our input was on 80-column punched cards - we had some hand-operated punches at school, and an obliging student who lived in Chelmsford ferried boxfuls to and from the College, also returning the lineprinter output they generated (mainly listings of program errors, but including the occasional burst of runtime results!).

Paper tape was a much less bulky storage medium, but we were only able to use it occasionally - by visiting a room full of noisy Westrex teletype machines at the College. The computer had its own paper tape punch, with which I created "backup" copies of working punched-card programs. A few of these have survived; in the photo are BRENTRAN (a set of numeric and string I/O procedures written in NEAT assembly language), and PTEDIT (a program to edit paper tapes, written in ALGOL 60). Sitting on top is a calendar generator, which I later wrote (reluctantly) in FORTRAN IV for an IBM computer in Cambridge (it's on ⅞ inch tape, 6 bits + parity, as opposed to the others which are 1 inch, 7 bits + parity). Note, in passing, my METC user number 3052, which predates username JOHNR by many years! Also, the "slashed" letter Os; that was the convention on their system, although it was generally more usual for the 0 (zero) character to be "slashed".

Having "discovered" those tapes in a cupboard, I thought it would be fun to write a program to read them, using a series of photos as input. My experimental Virtual Paper Tape Reader (VPTR) can decode up to about 50 inches of tape from a single photograph, provided it's laid out fairly straight on a dark background. That's 500 characters! I had an interesting time reading the first tape (BRENTRAN), including a grim reminder of the chaos that results when the centre of a rolled-up tape drops out. That used to be surpassed, in the computer room, only when a card-reader jam caused a magnificent spectacle known as a "card fountain". Pity the poor operators who had to crawl around the room picking up cards!

Early in 2022, encouraged by the comments of a visitor to this web page, I added some new features to VPTR and wrote a complementary program, VPTP, to encode text characters into an image resembling a length of paper tape. Both programs run under Microsoft Windows™, and experimental versions can be made available to enthusiasts on request.

VPTR's control panel is overlaid on a window which displays the text as it's recovered from the image. The Load button launches a standard open file dialogue, then the navigation buttons can be used to nudge the tape start into the viewport. Engage attempts to find and lock onto the nearest sprocket hole; if successful, green cross hairs and a decoded character, in Hexadecimal and Ascii, are displayed. The Right and Left buttons then respectively advance and backspace by one character. Read will attempt to read to the end of the tape, displaying the results in the text window and appending them to a buffer which can be written out to a text file by pressing Save , or exported to the clipboard with Copy . Clear clears the buffer and text window.

The software continually tracks the top and bottom tape edges, adapting to changes in tape dimensions, brightness and contrast. It also monitors the topmost (parity) track, measuring the horizontal offset of every hole from its datum, to calculate a "skew factor" that's used when detecting holes on all tracks. These provisions help in reading lower quality images but, as with physical tape readers, parity checking is useful for detecting errors if the tape format supports it. You can select Ignore Parity , Odd Parity or Even Parity . In the latter two cases, if a parity error is detected then any read in progress stops, the cross hairs turn red, and either the Hex code or the Ascii character can be edited. In the pictured example, the character "J" was subsequently corrected to "K", whereupon the cross hairs turned green and the Read button became available to continue.

The Virtual Punch, VPTP, has a similar control panel, but in its case the viewport shows the last two characters punched on the virtual tape. Check boxes on the left allow the Enter and Backspace keys to do their usual tricks during keyboard entry, but these can be unchecked if it is required just to punch CR or BS codes onto the tape. Inc File and Paste enable text to be included from a file or the clipboard. The Save button writes out the tape image to a bitmap file.

Future improvements? I'm tempted to extend the skew detection to all tracks, ultimately perhaps making the sprocket holes redundant (being smaller, they've proved to be the biggest problem at low image resolutions). One day I might combine VPTR with VPTP to make a Virtual Paper Tape Station based on a single window, and add options for different tape formats, such as the IBM one mentioned earlier.

For the amusement of fellow geeks, I've put a copy of the recovered BRENTRAN program here . Note that the tab positions were originally based on punched-card fields. Also, the backslash (\) originally rendered as a pound symbol (£), which was used, like the dollar in American software, to prefix system-defined names. In retrospect I should have used the latter in place of the various numeric addresses that appear in BRENTRAN, but, hey, I was only 16! I'll write more about the 4100 architecture, and runtime environment, in due course.

Table Of Contents

- How Data Is Represented

- What are the Sprocket Holes For?

- Building a Paper Tape Reader

Quick search

Reading punched paper tape ¶.

Just before we started ‘A’-level Computer Science, our school was provided with a TeleType ASR 33 that looked something like this one which is at the National Museum of Computing :

and an acoustic coupler, made by Modular Technologies, that we could use to connect to the local college’s ICL 2903 BASIC system. Here’s one, also at the National Museum of Computing:

Using this connection, we could develop the BASIC programs that would form part the coursework submitted as part of the examination. As you can see, on the left of the TeleType is a mechanical paper tape punch which would punch on paper tape exactly the same text that was being printed out so to save our programs off-line, we would turn the punch on and then list the program.

I still have some of these punched paper tapes and so I thought it would be interesting to recover them forty years later and see if they would still run on an emulator I am developing for the ICL 2903 Interactive BASIC System. Here’s the paper tape for one of my smaller programs:

How Data Is Represented ¶

If we take a closer look at part of the tape we can see that in each row of data (called a frame), there are spaces for nine holes, eight holding data and one row of smaller sprocket holes:

The eight data columns consist of one parity bit and seven bits holding the character code of the character each row represents: a hole is a binary ‘1’ and a missing hole is binary ‘0’. THe most significant bit of the code is held in the column I’ve labelled 7 and the least significant bit is in column 1. Hence, ignoring the parity column, the row indicated holds the seven data bits 1001110 which is 0x4E in hexadecimal. This is the ASCII character code for the character ‘N’.

The left-most column, labelled P, is the parity bit. Parity bits are used to provide a small amount of error checking by imposing the rule that the total number of data holes in each row must be even. In this case, columns 1..7 contain four holes and four is already even, so no parity hole is needed. The row below it has three holes in columns 1..7 so an extra hole is added in the parity column. When the tape is being read, if it reads an odd number of holes, the reader knows something has gone wrong.

The ICL 2903 system has its own system of character codes defining sixty four characters. The first thing the system needs to do when reading the paper tape is to convert the ASCII codes into its own internal equivalent.

Two values have a special meaning: 0, which is no holes, is not considered to be a character. This means that we can run out blank tape between characters with no effect. The value 128, which is eight holes (including the parity hole), is also ignored. This means that if we make a mistake when preparing the paper tape we can back up one position and delete it by punching through all of the holes.

If you decode the remaining frames in the piece of tape shown, you will end up with the text NEW UPDATE followed by a line-feed character, 0x0A, which marks the end of the line. This then is a command to the BASIC system telling it to clear any program it has previously loaded so we can start to enter a new one and that the new program’s name is to be UPDATE.

What are the Sprocket Holes For? ¶

You’ll notice that there’s a row of holes running down the tape between data columns 3 and 4. These are obviously sprocket holes that are used by the reader to feed the paper tape through the reading position but this isn’t their only purpose.

The sprocket holes are smaller than the data holes and the centre of each sprocket hole lines up the the centre of the data holes. This is used by the reader to detect when it’s time to read the data: when the reader detects the small sprocket hole, then the large data holes are safely in position to be read.

This means the paper tape is self-clocking - the speed at which it is physically drawn through the reader can vary freely while it is being read because the sprockets provide a “tick” telling the reader when the next frame is in position.

Building a Paper Tape Reader ¶

There aren’t many punched paper tape readers around these days outside of museums so I thought I might try making something myself that would last just long enough to read my tapes.

The first thing we need is to be able to recognise the difference between a hole and a space. There are three ways of doing this:

Mechanically: have spring-loaded pins that pop up when a hole passes over them but are forced down when there isn’t one. This is slow but the TeleType reader works like this because it only has to read at ten characters per second

Electromechanically: use conducting brushes on one side and a metal plate on the other. The paper prevents them making an electrical circuit when there’s a space but when there’s a hole, they connect and current flows.

Optically: use a light detector on one side of the tape and a light source on the other. More light passes through when there’s a hole between them and electronic components detect the change.

The first two are ruled out by my woefully poor mechanical engineering skills, so that leaves me with the optical option.

I bought some photodiodes, resistors and a breadboard along with an Arduino (a small system used by hobbyists for projects just like this). The photodiodes can detect the changing light levels - the more light, the more current they generate. The resistors are needed to limit the total amount of current flowing through the circuit to protect the photodiodes from burning out.

As an experiment, I connected a photodiode to the Arduino’s GND pin and one of its analogue I/O pins with a resistor in parallel with the photodiode and then ran an Arduino script to read the I/O pin level and send it up the serial line to the PC controlling the Arduino. This setup could reliably detect the difference between paper and hole and revealed that the photodiode was responsive enough to suggest it could read tape at a speed of the order of ten metres a second. My plan was to take advantage of the self-clocking nature of the tape and pull it through my reader by hand - ten metres a second is far faster than I could pull the tape without risking tearing it.

The next step was to build a little housing to hold the photodiodes and paper tape in position. I glued some scrap plastic sheets together to make a thick block of plastic and then drilled holes in it to hold the photodiodes below its surface. On top of these I added a thin sheet of plastic with smaller holes drilled in it so that the photodiodes only saw light from a small area over their centre.

Nine photodiodes are needed - eight for the data and one for the sprocket “clock” - but alas, the photodiodes were too large to fit side by side along one row so I had to stagger them:

This means that when the Arduino samples all of the photodiodes, it reads bit 8 of frame 1, bit 7 of frame 2 and so on down to bit 1 of frame 8. The next time, it will read bit 8 of frame 2, 6 of frame 3 down to bit 2 of frame 8 and bit 1 of frame 9. Only after reading eight frames will we have all of the bits of frame eight. From that point on, each new frame read completes the next frame.

Because of this, the reading software will have to keep track of which bits of which frames have been received and output frames as they are completed.

I decided to keep the Arduino script as simple and as fast as possible. All it does is read the raw levels of the nine analogue I/O pins and sends the results up the serial line to the controlling PC. Software running on the PC then inspects the level of the sprocket clock’s pin to detect when it is below a hole and so the other data pins are ready to process. It then converts their levels into hole/space values and reassembles each frame’s bits in turn.

Having got it all working, all that remained was for me to uncoil each roll of paper tape for the first time in nearly forty years, set the software running and pull the tape through the device. I erred on the side of caution and pulled at around a metre per second. This is a data rate of about 400 frames a second.

Here’s the device in all its glory ready for use supported on some books for stability:

It’s rather Heath-Robinson in appearance and please don’t laugh too much at my soldering skills - it’s the first time I’ve done any electronics at all other than a few exercises with 7400-series logic chips and a breadboard one week at college. Just be as astonished as I was that it worked to do the job it was designed to do and no more.

Finally, for completeness, here’s what was on the paper tape you saw at the top of this article. It turns out to be part of a suite of programs I wrote to deal with the distribution of examination results to pupils. THis program is a fairly traditional batch update of an input data set inserting, deleting and replacing records to generate a new output data set:

To be sure, it’s not the greatest program I ever wrote but bear in mind that the code we wrote as part of the course was aimed at learning something, not developing correct, maintainable software. On the plus side, it does avoid what was claimed to be the commonest bug in data processing applications: reaching the end of one data stream and forgetting to copy the rest of the other to the output.

- Collections

- Publications

- K-12 Students & Educators

- Families & Community Groups

- Colleges & Universities

- Business & Government Leaders

- Make a Plan

- Exhibits at the Museum

- Tours & Group Reservations

- Customize It

- This is CHM

- Ways to Give

- Donor Recognition

- Institutional Partnerships

- Upcoming Events

- Hours & Directions

Artifact Details

Catalog Number

Description, manufacturer, place manufactured, identifying numbers, linked resources.

- [itemResources.val;block=li;noerr]

Related Records

PC04/PC05 High-Speed Paper-Tape Reader/Punch

The PC04 and PC05 Paper-Tape Reader/Punches are the DEC -supplied paper tape peripherals for the PDP-8 and PDP-11 respectively. The '04 was also used by the PDP-9 and early PDP-10 models, and '05 by the PDP-12 and PDP-15 .

The mechanical portions are the same in the '04 and '05 types, but they differ in the control electronics in them. Both types include an electro-mechanical punch (a Roytron Model 500, modified by DEC), and a photo-electric reader (manufactured by DEC), which are completely separate, but housed in the same frame, and share a power supply .

There are also reader-only and punch-only models: the reader-punch model of the PC04 is the PC04B , the reader-only model is the PC04R , and the punch-only model is the PC04P ; the reader-punch model of the PC05 is the PC05C , the reader-only model is the PC05R , and the punch-only model is the PC05P .

All the models listed above come in 50Hz and 60Hz versions (which are identical except for the punch pulley; so there are no separate 50Hz versions of the reader-only models).

There is also a backplane to hold the control electronics, which are a number of FLIP CHIPs . The backplane in the PC04 has 8 slots; that in the PC05 has 12 slots. (In addition, there is also a controller in the computer.)

- 4 Mounting slides

- 5 External links

There are a myriad of different versions, in addition to the variants above, particularly in the '04.

To start with, there are two generations of each type: in the earlier, input data is strobed during reading by a signal from the stepper motor; the later strobes the data by sensing the feed holes. No documentation has yet been located on the earlier generation, but there was an ECO to upgrade units to the later.

There are also different versions of the PC04 for different PDP-8 models (they differ as to which FLIP CHIPs are used, as per the tables below):

- PC04-B, PC04-C - PDP-8, PDP-8/S (also the PDP-9 and KA10 )

- PC04-BB - PDP-8/I

- PC04-BL - PDP-8/E, PDP-8/F, PDP-8/L, PDP-8/M

along with equivalent versions of the punch-only and reader-only models.

(There is disagreement between the May 1973 revision of the manual, DEC-00-PC0A-D, and the April 1972 revision of the engineering drawings as to the version numbers. The ones above are from the drawings, which also do not show a punch-only model for the -8/I, with the reader-only version for that being the PC04-RB; the manual claims the -8/I reader-only and punch-only versions are the PC04-R and PC04-P, which the prints list as being for the -8 and -8/S.)

There is also a special version of the reader/punch model for the KI10 , the PC04-CL. The 50Hz versions of all of these differ in the last letter, which is incremented; e.g. the KI10 50Hz version is the -CM.

The control switch array on the front panel differs between the reader-punch, reader-only, and punch-only versions; the PDP-10 versions have their own switch array formats. Also, the '05 does not have a 'Punch On' switch, as the PC11 can turn the punch on and off remotely.

The cable arrangements for the '04 and '05 are almost as complicated as the model/version situation!

All have a single-width PCB with plated contact fingers at one end, to plug into the backplane in the PC04/05; the connector on the other end varies, depending on what it goes to.

The early PDP-8 models use cables with a PCB on both ends, and the PDP-8 end plugs into a slot in its backplane. The -8/E uses BC08K cables, which have an M955 PCB on the PC04 end, and a 40-pin male-shell Berg connector on the other end, which goes into female Berg headers on an M840 plugged into the OMNIBUS .

This is the pinout of the BC08K:

Pins of the Berg connector which aren't listed in the table are connected to ground .

There are two different versions of the PC11 controller , and they use different cables. The early version (with a separate dual card) uses Flexprint cable BC08F's, which have a right-angle PCB on the other end, which plugs into a connector on the side of the M781 card. The later quad-width version uses flat cable BC08Js, which have an M953 on the PC05 end, and a 40-pin male-shell Berg connector on the end which goes into the M7810.

Note: The BC08J looks identical to the BC08K used with the PC04, but they have a different pinout. This is the pinout of the BC08J:

Similarly to the BC08K, pins of both the Berg connector and the PCB which aren't listed in the table are connected to ground .

Electronics

The tables below show the FLIP CHIPs used in each version; the location of boards which end cables, and are plugged into the backplane to carry signals to/from the backplane, are also shown. Cards/cables used for the punch are shown in italics ; the others are for the reader. Reader-only and punch-only models will have only the associated cards/cables.

The M705 Reader control card was later replaced by the M7050; the K303 was not included when later revisions of the M710 Punch control card were used.

Mounting slides

PC04's can be rack-mounted in 19" rack (such as an H960 rack ) with the use of General Devices Chassis Trak telescoping slides number C-300 8-31-8, which have the proper hole pattern in the innermost slide to bolt to the PC04. Other slides can of course be used, but will likely require custom hole-drilling.

External links

- PC04/PC05 paper-tape reader/punch (feed-hole strobed) (DEC-00-PC0A-D)

- PC04/PC05 paper tape reader/punch engineering drawings

- Roytron Model 500 Maintenance Manual - Punch manual

- PC05 High-Speed Paper-Tape Reader / Punch

- DEC PC05 paper tape reader/puncher

- DEC PC05 - Model evolution

- DEC PC05 - Failures

- DEC Peripherals

- DEC Documentation Errors

Navigation menu

- View source

Personal tools

- Recent changes

- Wanted pages

- Random page

- Pages with prefix

- What links here

- Related changes

- Special pages

- Printable version

- Permanent link

- Page information

- This page was last edited on 28 February 2023, at 08:14.

- Content is available under GNU Free Documentation License 1.2 unless otherwise noted.

- Privacy policy

- About Computer History Wiki

- Disclaimers

Build your own solar eclipse viewer with a cereal box: Easy DIY instructions

Homemade pinhole eclipse viewers an alternative to fancy glasses for viewing solar eclipse on april 8. only a sliver of michigan will be in the path of totality, when moon completely covers the sun..

Eclipses, like the solar eclipse coming up on April 8 , are some of the sky's most spectacular shows. And there are multiple ways to view them safely.

You don't necessarily need special glasses or filters , but it takes a little creativity and a handful to household supplies to make your own pinhole box or pinhole projector, also known as a pinhole camera.

Here's what to know about building your own eclipse viewer.

How to build your own eclipse viewer

One method simply involves two sheets of sturdy white paper, a cereal box and another sheet of paper. The other supplies you need: tape and aluminum foil, scissors, and a pin or thumbtack.

Here's how to make a pinhole viewer with a cereal box:

- Trace a piece of white paper along the bottom of the box, making sure it will fit the bottom of the box, and tape or glue it into place it inside the box.

- Seal the top of the box, then cut rectangular holes on the right and left sides of the top of the box.

- Cut a piece of aluminum foil to cover the top left hole and tape in place. Make sure the foil is flat and not crinkled.

- Poke a pinhole in the center of the foil.

- During the eclipse, stand with the sun behind you, and look into the right hole at the top of the box and watch a projection of the eclipsed sun on the paper inside.

Here's another do-it-yourself option:

- Cut a 1- to 2-inch rectangular hole in a white sheet of cardstock — paper that is sturdier than regular paper and thinner than cardboard (the kind used for business cards and postcards). A paper plate will do as well. Place a smooth piece of aluminum foil over the hole.

- Flip the paper over, and use a pin or thumbtack to poke a small hole in the foil.

- During the eclipse, place a second piece of cardstock, or paper plate, on the ground, and hold the piece with the aluminum foil above the paper, making sure the foil is facing up. Stand with the sun behind you and view the projected image on the cardstock. The farther apart the sheets of cardstock are from each other, the bigger the projected image will be.

- You can also try putting the bottom piece of cardstock in a shadowed area, while holding the other piece in the sunlight.

Other ideas: Poke several holes in the foil to make shapes, patterns or other designs. Use various household items that have multiple small holes, such as a colander or steamer, and view the patterns they create, but make sure your back is to the sun.

And don't forget to grab a helper to take photos of your designs.

These projectors are known as pinhole cameras because the small hole you made acts like a tiny camera lens. Light from the sun enters the pinhole (or colander), gets focused and then projected to the other side of the hole. When the projected light reaches the surface, like the second sheet of cardstock, you can see the image that passed through the pinhole.

More: 2024 total solar eclipse to be visible in sliver of Michigan: Where map shows to go

Don't forget: it's not safe to look directly at the sun during the eclipse, and sunglasses don't provide protection. If you're using special glasses, make sure they meet the ISO standard 12312-2. NASA does not endorse specific eyewear for viewing the eclipse.

Source: NASA

Contact Jennifer Dixon: [email protected]

Forgot to get solar eclipse glasses? Here's how to DIY a viewer with household items.

By now, everyone has heard that the rare 2024 total solar eclipse is coming – and it's got people excited.

While cities brace for traffic, schools brace for absences and space enthusiasts are planning parties, the glasses that enable safe viewing of the eclipse have become something of a hot commodity.

Peeking directly at the eclipse before it reaches totality without proper eye protection can cause permanent eye damage, experts have warned, making glasses a necessity for safe viewing. But, as the day approaches, they may become harder to find .

Luckily, people who didn't manage to get their hands on glasses are not completely down and out. There are other safe ways to view the eclipse, say experts, and a lot of them only require a little bit of craftiness and items you can find lying around the house.

Here are a few DIY eclipse viewers you can make at home.

As a reminder, none of these options allow you to look directly at the eclipse: you need special eclipse glasses for that.

Solar eclipse guide: When is the 2024 total solar eclipse? Your guide to glasses, forecast, where to watch.

NASA's DIY cereal box viewer

This NASA project uses components you almost certainly already have at home. Using a cereal box, cardboard, foil, paper, scissors and tape or glue, you can put together this projection eclipse viewer.

As always, NASA advises not to look directly into the sun using this tool.

Steps to make the cereal box eclipse viewer:

- Get an empty, clean cereal box.

- Cut a white piece of cardboard that will fit snuggly in the bottom of the box, or secure it permanently by gluing it in place.

- Cut the top of the cereal box, removing both ends and leaving the center intact.

- Put a piece of tape across the center of the top to securely hold it closed.

- Tape a piece of heavy-duty foil or double a single layer for additional strength, covering one of the openings at the top of the cereal box. The other opening will remain open for viewing.

- Using a small nail (approximately 3mm in diameter) push a hole in the foil.

- Cover the entire box with construction paper, leaving the single-viewing opening and the foil uncovered.

How to use the DIY viewer :

- The finished box should be held with the pin-hole side facing the sun. It may take a little practice pointing the box.

- With your back facing the sun, look through the viewing opening. A small image of the sun, about ½ cm in diameter can be seen projected on the white paper inside the box.

Watch the demo here:

The Planetary Society DIY paper viewer

While the Planetary Society also offers instructions for box or projector viewers that are more "fancy," as they put it, it doesn't get easier than their simple pinhole paper projector.

To make it, you only need two index cards (3-by-5 or A6 or A7 size) or small paper plates for each person and basic pushpins. Simply use the pushpin to punch a small hole close to the middle of one of the cards and you're done.

Another super easy version that requires no crafting? A kitchen colander. An ordinary kitchen colander can easily be used to view a solar eclipse in the same way as other projector viewers; the colander's circular holes project crescent images of the sun onto the ground.

To make the "fancier" version, you'll need 2 index cards (larger, 5-by-7 or A5 cards work better for this) or small paper plates for each person, a pencil, pushpins and a towel, sweatshirt, blanket, flattened corrugated cardboard box, carpet, or other soft substrate to place underneath card during pin pushing.

To make the fancier version:

- Draw a simple design on a card. The lines should not be too close together

- Place the card on top of something soft (blanket, towel, etc)

- Using the push pin, make small holes along your design lines. Not too close together – about 5 millimeters (1/4 inch) apart.

To use it, you'll again want to avoid looking directly at the sun:

- Go to your eclipse observing spot and make sure you can see the shadow of your head and shoulders clearly.

- Hold up the card with the hole on top of your shoulder so that you can see the shadow of the card above the shadow of your shoulder.

- Now hold up the other card and make sure you can see its shadow, too.

- Move the second card and watch how its shadow moves. Keeping the card in front of you, move its shadow until the second card's shadow overlaps the first card's shadow.

- Now look at the second card. You should see a dot on the card for every hole you punched. Those dots are actually images of the sun.

Cardboard or paper tube eclipse viewer

Sticking with the theme of using items you can easily find around the house, tube viewers can be made using cardboard tubes from household items like paper towels or toilet paper rolls. You can also use thick cardstock rolled up and taped to make your own tube.

To make one, you'll need a cardboard tube, white paper, aluminum foil, tape and a pushpin or something else sharp to poke a small hole. According to "Let's Talk Science," you can put this viewer together with these steps :

- Trace the opening of the tube on a piece of white paper. Draw a slightly bigger circle around it. Cut around the bigger circle. Cut small slits to the inner circle.

- Cut an opening near one end of the tube to make a viewing window.

- Tape the paper circle to the end of the tube near the viewing window.

- Cut a piece of aluminum foil that is a bit larger than the opening of the tube.

- Poke a small hole in the center of the aluminum foil.

- Tape the aluminum foil over the other opening of the tube.

How to use the viewer:

- With your back to the sun, hold the tube parallel to the path of the sun. Look through the viewing hole. Move the viewer until a small white circle appears on the paper.

See an example below:

Can't find solar eclipse glasses? Here's how to make a last-minute pinhole camera

A cereal box, tape, aluminum foil and paper will do the trick.

These kids are using cereal boxes and tape to get a safe look at the solar eclipse

Social sharing.

Kids in Newfoundland and Labrador are gearing up to view their first-ever solar eclipse, an experience they say is bound to be exciting, but a tad scary.

The little ones want to make sure their eyes are protected when they watch the moon pass over the sun — to do so, they've learned how to make pinhole cameras, or solar eclipse viewers.

On Saturday, the A.C. Hunter Public Library in St. John's taught people how to make the cameras using a cereal box or shoebox, aluminum foil, tape and a white sheet of paper.

If you can't find solar eclipse glasses and are looking for a quick and safe last-minute alternative, check out the video below for a step-by-step guide on how to make your own pinhole camera.

Can’t find eclipse glasses? Here’s how to make a quick and easy pinhole camera

Download our free CBC News app to sign up for push alerts for CBC Newfoundland and Labrador. Click here to visit our landing page .

Related Stories

- N.L. is getting a front-row seat to the rare total solar eclipse. Here's everything you need to know

Add some “good” to your morning and evening.

Subscribe to our daily newsletter for the top stories in Newfoundland and Labrador.

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.

Sean 'Diddy' Combs allegations: Timeline and what to know

Sean “ Diddy ” Combs has been hit with a wave of civil lawsuits in recent months and is now a subject of a federal investigation, sources have told NBC News.

Federal agents this week executed searches of Combs’ properties , where guns were found, and his phones were seized at an airport as part of a warrant issued from the U.S. District Court for the Southern District of New York, law enforcement sources have said.

Since November, Combs has been hit with five lawsuits in New York accusing him of sexual assault, sexual trafficking and engaging in other criminal activity. Combs has denied all of the allegations, calling them sickening.

A source familiar with the matter told NBC News that at least four people have been interviewed about allegations of sex trafficking, sexual assault and the solicitation and distribution of illegal narcotics and firearms.

Aaron Dyer, an attorney for Combs, described the raids this week as a “gross overuse of military-level force.” Neither Combs nor any of his family members have been arrested, Dyer noted in his statement.

Here are the lawsuits that were filed against Combs prior to the raid. Combs has denied all of the allegations individually through statements by his representatives.

November 2023: Cassie and two others file suit

The singer Cassie, Combs’ former romantic partner, shocked many in November when she filed a civil suit against Combs alleging that the music mogul sexually and physically abused her during the course of their relationship. She filed her case on Nov. 16 under New York state’s Adult Survivors Act, which gave adult victims of sexual violence a one-year window to file civil claims regardless of the statute of limitations.

In the suit, Cassie alleged that Combs raped her, beat her in fits of “uncontrollable rage” and exerted a “tight hold over her life.” She alleged that he would force her to engage in sex acts he called “Freak Offs” with other men, often sex workers whom he’d pay to travel with them, while he watched.

The abuse ranged from 2007 until Cassie left him in late 2018, the suit said.

Combs vehemently denied the allegations from Cassie, whose full name is Casandra Ventura. They settled the suit a day after it was filed.

Joi Dickerson-Neal said Cassie’s lawsuit inspired her to come forward and file a suit against Combs on Nov. 23, a day before the Adult Survivors Act was set to expire.

Dickerson-Neal said that Combs drugged her, sexually assaulted her and recorded the assault without her knowledge while she was a student in 1991. She agreed to have dinner with Combs on Jan. 3, 1991, in Harlem while on winter break from Syracuse University, according to her suit.

It was there that Combs “intentionally drugged” her and then took her to a place where he was staying, the suit said. Dickerson-Neal said she “lacked the physical ability or mental capacity to fend Combs off” as he sexually assaulted her.

She later learned from a male friend that Combs had filmed the assault and showed it to other people, the suit said. Combs denied her allegations.

On the last day of eligibility under the Adult Survivors Act, Liza Gardner filed a lawsuit accusing Combs of sexually assaulting her when she was 16 years old.

Gardner alleged that in either 1990 or 1991 she and a friend met Combs and R&B singer Aaron Hall at an event held by MCA Records in Manhattan. After the party, she was invited back to Hall’s apartment with Combs, the suit said, and the two offered her drinks throughout the night.

Combs then coerced her into having sex, the suit said, leaving Gardner “shocked and traumatized.” Hall barged into the room after Combs was done, pinned her down, and sexually assaulted her, according to the suit.

Hall did not return NBC News’ request for comment on the lawsuit. Combs denied Gardner’s allegations in a statement through his representative.

December 2023: Jane Doe says she was gang-raped at 17

Then in December, a Jane Doe filed a lawsuit alleging that she was gang-raped and sex-trafficked by Combs and Harve Pierre, a former longtime president of Combs’ record label. The unidentified woman said the assault happened in 2003, when she was 17 and Combs was 34.

According to the suit, she met Combs and Pierre at a lounge in Detroit and Combs convinced her to travel with them on a private jet to New York City. Before they left the lounge, the suit said, Pierre smoked crack cocaine and forced Doe to perform oral sex on him.

Doe was taken to a studio in New York City, where Combs, Pierre and a third defendant plied her with “copious amounts of drugs and alcohol,” the suit said. The three men took turns raping her in a bathroom at the studio after she was too inebriated to consent, according to the suit.

The men allegedly left her on the bathroom floor once they were done and she was flown back to Michigan, the suit said. Combs denied the assault allegations and Pierre called the suit “a tale of fiction.”

February 2024: Rodney Jones accuses Combs of ‘RICO enterprise’

In February, a man named Rodney “Lil Rod” Jones alleged in a federal suit that Combs and his associates engaged in “serious illegal activity.”

Jones worked as a producer on Combs’ latest album, but also lived and traveled with him from September 2022 to November 2023, according to his lawsuit. He alleged that during that time he was sexually harassed by Combs, pressured to engage in sexual acts, forced to procure sex workers for Combs and witnessed Combs giving drinks laced with drugs to people at parties.

The suit said that Combs required Jones to “record him constantly,” which resulted in Jones obtaining hours of footage in which Combs and his staff allegedly engaged in criminal conduct. Screenshots of video clips were included in the suit, described as being from parties in which underage girls and sex workers were present.

Jones alleged that Combs was attempting to groom him into having a sexual relationship with him. The lawsuit said that Combs sexually harassed and assaulted Jones while he lived at Combs’ homes in Florida, Los Angeles and New York, as well as on a yacht Combs rented in the U.S. Virgin Islands.

Jones alleged that he and another man, Brendan Paul, were asked to travel with drugs and firearms on Combs’ behalf.

In amended filings, Jones additionally accused Combs and his son of being involved in a 2022 shooting at a Los Angeles recording studio , which both men denied.

An attorney for Combs said Jones’ “reckless name-dropping about events that are pure fiction and simply did not happen is nothing more than a transparent attempt to garner headlines.”

March 2024: Combs’ homes searched by federal agents

On March 25, agents with Homeland Security Investigations raided Combs’ properties in Los Angeles and Miami. Three sources familiar with the matter told NBC News that firearms were found at his residences, but no additional details were provided.

At the time of the raids, Combs was on his way to a scheduled trip to the Bahamas and was stopped at a Miami airport prior to departure. Officials seized his cellphones, sources said.

Dyer, one of Combs’ attorneys, issued a statement following the raids and said that Combs “was never detained but spoke to and cooperated with authorities.” He described the raid as an ambush, saying there’s been a rush to judgment based on “meritless accusations made in civil lawsuits.”

“There has been no finding of criminal or civil liability with any of these allegations,” Dyer said. “Mr. Combs is innocent and will continue to fight every single day to clear his name.”

Brendan Paul, 25, was arrested at the Miami-Opa Locka Executive Airport at the same time Combs was stopped at the airport. A law enforcement source familiar with the matter confirmed that Paul is a Combs associate. It is currently unclear whether the arrest was related to the raids.

Paul was named as an employee of Combs’ in Jones’ suit, which described him as someone who acquires and distributes drugs and guns on Combs’ behalf. Combs allegedly required Paul and others he paid to carry black pouches that contained drugs such as ecstasy, cocaine, ketamine, marijuana and mushrooms.

A Miami-Dade police report showed Paul was charged with possession of suspected cocaine and suspected marijuana candy, and court records show he was bonded out of custody the next day.

According to the police report, local law enforcement was with agents from Homeland Security and customs officers at the time of Paul’s arrest. The contraband items were found in Paul’s travel bags, the report said.

Paul’s attorney, Brian Bieber, told NBC News, “We do not plan on trying this case in the media — all issues will be dealt with in Court.” A woman who answered the phone at a number listed for Paul hung up on an NBC News reporter.

April 2024: Combs' son, Christian Combs, is accused of sexual assault

Grace O’Marcaigh alleges in a lawsuit that Christian Combs drugged and sexually assaulted her while she was working on a yacht the elder Combs had chartered for a trip at the end of 2022. The suit also names Sean Combs as a defendant. The assault is alleged to have occurred days before Sean Combs hosted a New Year’s Eve yacht party with celebrity guests . O'Marcaigh included as evidence transcriptions of audio clips — that were recorded by a producer — of her denying his advances as he gropes her. NBC News has heard two clips of audio transcribed in the suit purportedly from the night of Dec. 28, 2022, but has not verified who was recorded.

Representatives for Christian and Sean Combs did not immediately respond to a request for comment.

CORRECTION (April 2, 2024, 9:40 a.m. ET): A previous version of this article misspelled the first name of one of Combs’ accusers. She is Joi Dickerson-Neal, not Joie.

Doha Madani is a senior breaking news reporter for NBC News. Pronouns: she/her.

Diana Dasrath is entertainment producer and senior reporter for NBC News covering all platforms.

Andrew Blankstein is an investigative reporter for NBC News. He covers the Western U.S., specializing in crime, courts and homeland security.

April 2, 2024

How to Photograph a Total Solar Eclipse with Any Camera

We asked a professional astro photographer and eclipse chaser how to take the best photographs and videos of a total solar eclipse.

By Lucie McCormick & Kelso Harper

On supporting science journalism

If you're enjoying this article, consider supporting our award-winning journalism by subscribing . By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

This article is part of a special report on the total solar eclipse that will be visible from parts of the U.S., Mexico and Canada on April 8, 2024.

A total solar eclipse is a rare, often once-in-a-lifetime event. So we asked Lucie McCormick, a professional astrophotographer and eclipse chaser, how to capture an eclipse using any camera you have.

Here’s what not to do to safely watch the total solar eclipse

We want you to have an excellent eclipse. This requires planning, research, some equipment. A total solar eclipse isn’t the kind of thing where you can just wing it.