Geography Notes

Essay on biomass: top 7 essays | india | bio energy | energy management.

ADVERTISEMENTS:

Here is a compilation of essays on ‘Biomass’ for class 7, 8, 9, 10, 11 and 12. Find paragraphs, long and short essays on ‘Biomass’ especially written for school and college students.

Essay on Biomass

Essay Contents:

- Essay on the Scenario of Biomass Energy in India

Essay # 1. Introduction to Biomass:

Biomass a renewable energy source is biological material from living or recently living organisms, such as wood, waste, (hydrogen) gas and alcohol fuels. Biomass is commonly plant matter grown to generate electricity or produce heat. In this sense, living biomass can also be included, as plants can also generate electricity while still alive.

The most conventional way in which biomass is used however, still relies on direct incineration. Forest residues for example (such as dead trees, branches and tree stumps), yard dipping, wood chips and garbage are often used for this.

However, biomass also includes plant or animal matter used for production of fibers or chemicals. Biomass may also include biodegradable wastes that can be burnt as fuel. It excludes organic materials such as fossil fuels which have been transformed by geological processes into substances such as coal or petroleum.

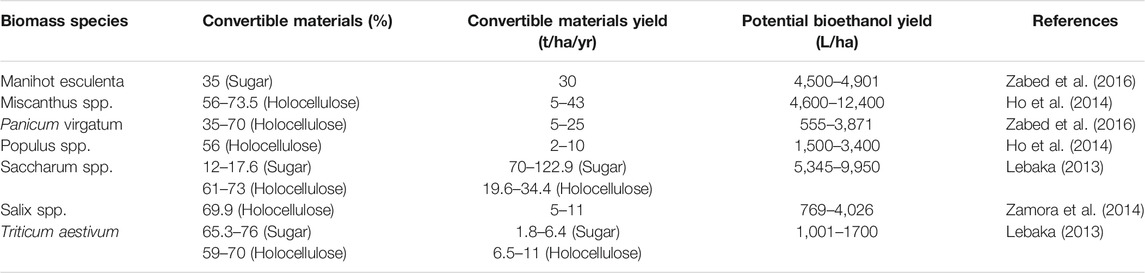

Industrial biomass can be grown from numerous types of plants, including miscanthus, switch-grass, hemp, corn, poplar, willow, sorghum, sugarcane and a variety of tree species, ranging from eucalyptus to oil palm (palm oil). The particular plant used is usually not important to the end products, but it does affect the processing of the raw material.

Although fossil fuels have their origin in ancient biomass, they are not considered biomass by the generally accepted definition because they contain carbon that has been ‘out’ of the carbon cycle for a very long time. Their combustion therefore disturbs the carbon dioxide content in the atmosphere.

Biomass is carbon, hydrogen and oxygen based. Nitrogen and small quantities of other atoms, including alkali, alkaline earth and heavy metals can be found as well. Metals are often found in functional molecules such as the porphyrins which include chlorophyll which contains magnesium.

Plants in particular combine water and carbon dioxide to sugar building blocks. The required energy is produced from light via photosynthesis based on chlorophyll. On average, between 0.1 and 1% of the available light is stored as chemical energy in plants. The sugar building blocks are the starting point for the major fractions found in all terrestrial plants, lignin, hemicellulose and cellulose.

Biomass does not add carbon dioxide to the atmosphere as it absorbs the same amount of carbon in growing as it releases when consumed as a fuel. Its advantage is that it can be used to generate electricity with the same equipment that is now being used for burning fossil fuels.

Biomass is an important source of energy and the most important fuel worldwide after coal, oil and natural gas. Bio-energy, in the form of biogas, which is derived from biomass, is expected to become one of the key energy resources for global sustainable development. Biomass offers higher energy efficiency through form of Biogas than by direct burning.

Application:

Bio energy is being used for- Cooking, mechanical applications, pumping, power generation.

Some of the devices- Biogas plant/gasifier/burner, gasifier engine pump sets, Stirling engine pump sets, producer gas/biogas based engine generator sets.

Essay # 2. Sources of Biomass:

Biomass energy is derived from five distinct energy sources:

(i) Garbage,

(iii) Waste,

(iv) Landfill Gases, and

(v) Alcohol Fuel.

Wood energy is derived both from direct use of harvested wood as a fuel and from wood waste streams. The largest source of energy from wood is pulping liquor or ‘black liquor’, a waste product from processes of the pulp, paper and paperboard industry.

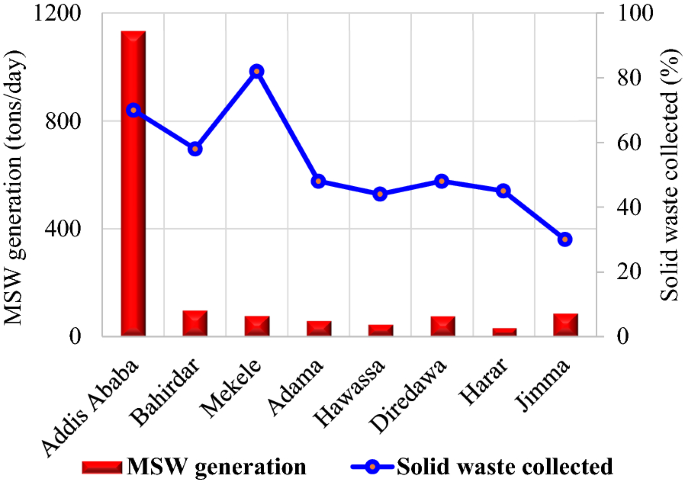

Waste energy is the second-largest source of biomass energy. The main contributors of waste energy are municipal solid waste (MSW), manufacturing waste and landfill gas. Biomass alcohol fuel or ethanol is derived primarily from sugarcane and corn. It can be used directly as a fuel or as an additive to gasoline.

Biomass can be converted to other usable forms of energy like methane gas or transportation fuels like ethanol and biodiesel. Methane gas is the main ingredient of natural gas. Smelly stuff, like rotting garbage and agricultural and human waste, release methane gas – also called ‘landfill gas’ or ‘biogas’.

Crops like corn and sugar cane can be fermented to produce the transportation fuel, ethanol. Biodiesel, another transportation fuel, can be produced from left-over food products like vegetable oils and animal fats. Also, biomass to liquids (BTLs) and cellulosic ethanol are still under research.

Essay # 3. Energy Conversion Process for Biomass:

There are a number of technological options available to make use of a wide variety of biomass types as a renewable energy source. Conversion technologies may release the energy directly, in the form of heat or electricity, or may convert it to another form, such as liquid biofuel or combustible biogas. While for some classes of biomass resource there may be a number of usage options, for others there may be only one appropriate technology.

(i) Thermal Conversion:

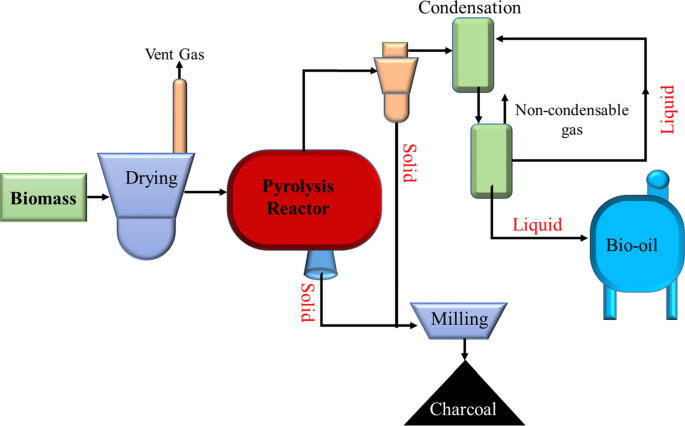

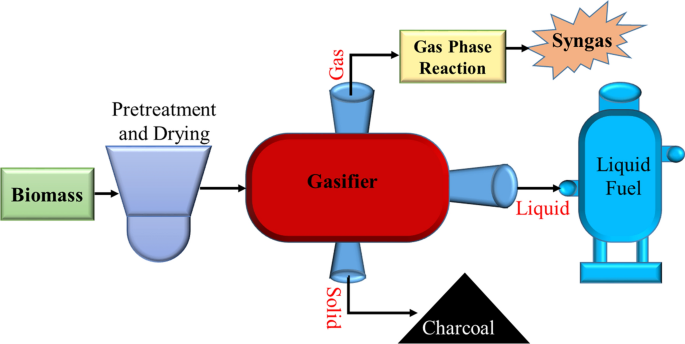

These are processes in which heat is the dominant mechanism to convert the biomass into another chemical form. The basic alternatives are separated principally by the extent to which the chemical reactions involved are allowed to proceed (mainly controlled by the availability of oxygen and conversion temperature): Combustion, Torre faction, Pyrolysis, Gasification.

There are a number of other less common, more experimental or proprietary thermal processes that may offer benefits such as hydrothermal upgrading (HTU) and hydro processing. Some have been developed for use on high moisture content biomass, including aqueous slurries and allow them to be converted into more convenient forms.

Some of the applications of thermal conversion are combined heat and power (CHP) and co-firing. In a typical biomass power plant, efficiencies range from 20-27 %.

(ii) Chemical Conversion:

A range of chemical processes may be used to convert biomass into other forms, such as to produce a fuel that is more conveniently used, transported or stored or to exploit some property of the process itself.

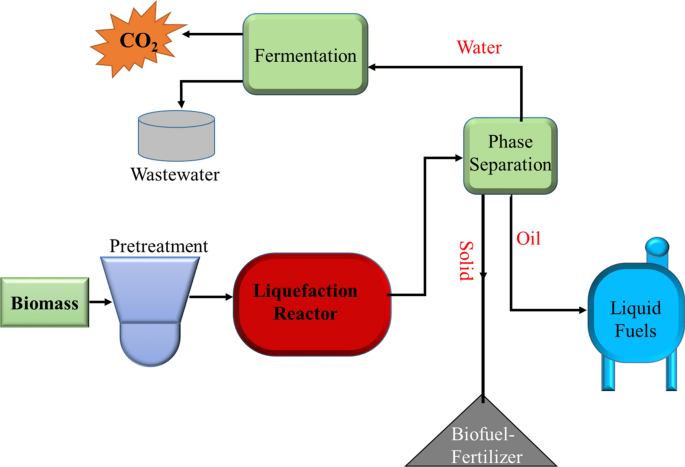

(iii) Biochemical Conversion:

A microbial electrolysis cell can be used to directly make hydrogen gas from plant matter. As biomass is a natural material, many highly efficient biochemical processes have developed in nature to break down the molecules of which biomass is composed and many of these biochemical conversion processes can be harnessed.

Biochemical conversion makes use of the enzymes of bacteria and other micro-organisms to break down biomass. In most cases micro-organisms are used to perform the conversion process: anaerobic digestion, fermentation and composting.

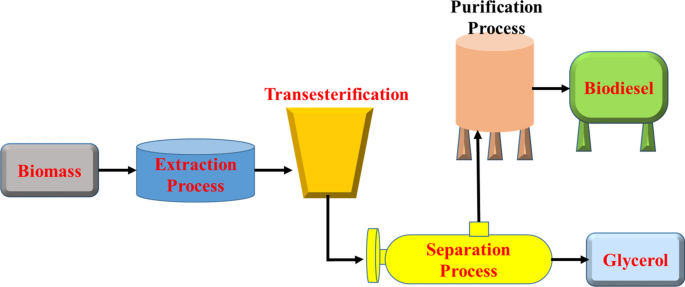

Other chemical processes such as converting straight and waste vegetable oils into biodiesel is trans-esterification. Another way of breaking down biomass is by breaking down the carbon-hydrates and simple sugars to make alcohol. However, this process has not been perfected yet. Scientists are still researching the effects of converting biomass.

Essay # 4. Applications of Biomass Energy:

The practical application of biomass energy includes:

(i) Bio-Gas Plants,

(ii) Biomass Briquetting,

(iii) Electricity Generation, and

(v) Bio Fuel etc.

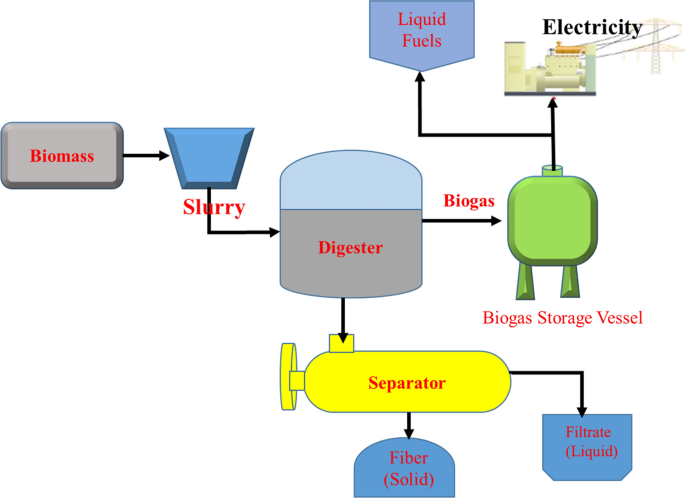

(i) Biogas Plants:

Biogas is a clean and efficient fuel, generated from cow-dung, human waste or any kind of biological materials derived through anaerobic fermentation process. The biogas consists of 60% methane with rest mainly carbon-di-oxide. Biogas is a safe fuel for cooking and lighting. By-product is usable as high-grade manure.

A typical biogas plant has the following components:

A digester in which the slurry (dung mixed with water) is fermented, an inlet tank – for mixing the feed and letting it into the digester, gas holder/dome in which the generated gas is collected, outlet tank to remove the spent slurry, distribution pipeline(s) to transport the gas into the kitchen and a manure pit, where the spent slurry is stored.

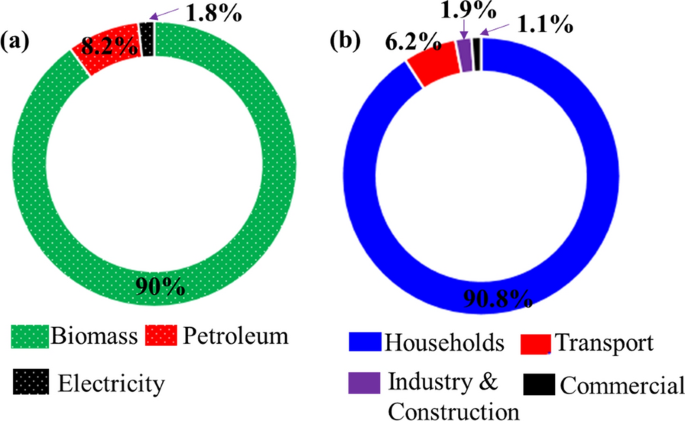

Biomass fuels account for about one-third of the total fuel used in the country. It is the most important fuel used in over 90% of the rural households and about 15% of the urban households. Using only local resources, namely cattle waste and other organic wastes, energy and manure are derived. Thus, the biogas plants are the cheap sources of energy in rural areas. The types of biogas plant designs popular are floating drum type, fixed dome-type and bag-type portable digester.

(ii) Biomass Briquetting:

The process of densifying loose agro-waste into a solidified biomass of high density, which can be conveniently used as a fuel, is called biomass briquetting. Briquette is also termed as “bio-coal”. It is pollution free and eco-friendly. Some of the agricultural and forestry residues can be briquetted after suitable pre-treatment.

A list of commonly used biomass materials that can be briquetted are given below:

CornCob, JuteStick, Sawdust, PineNeedle, Bagasse, CoffeeSpent, Tamarind, CoffeeHusk, AlmondShell, Groundnutshells, CoirPith, BagaseePith, Barleystraw, Tobaccodust, RiceHusk, Deoiled Bran.

Advantages:

Some of advantages of biomass briquetting are high calorific value with low ash content, absence of polluting gases like sulphur, phosphorus fumes and fly ash – which eliminate the need for pollution control equipment, complete combustion, ease of handling, transportation and storage because of uniform size and convenient lengths.

Biomass briquettes can replace almost all conventional fuels like coal, firewood and lignite in almost all general applications like heating, steam generation, etc. It can be used directly as fuel instead of total in the traditional chulhas and furnaces or in the gasifier. Gasifier converts solid fuel into a more convenient-to-use gaseous form of fuel called producer gas.

(iii) Electricity Generation using Biomass:

From the ancient time to the present, the most common way to capture the energy from biomass was to burn it to make heat. Since the industrial revolution this biomass fired heat has produced steam power and more recently this biomass fired steam power has been used to generate electricity. Burning biomass in conventional boilers can have numerous environmental and air-quality and advantages over burning fossil fuels.

Advances in recent years have shown that there are even more efficient and cleaner ways to use biomass. It can be converted into liquid fuels, for example or “cooked” in a process called “gasification” to produce combustible gases, which reduces various kinds of emissions from biomass combustion, especially particulates.

Electricity Generation using Biomass Gassifier:

Biomass gasifiers convert the solid biomass (basically wood waste, agricultural residues, etc.) into a combustible gas mixture normally called as producer gas. The conversion efficiency of the gasification process is in the range of 60-70%. The producer gas consists of mainly carbon-monoxide, hydrogen, nitrogen gas and methane and has a lower calorific value (1000-1200 kCal/Nm 3 ).

The ‘Biomass Gasification – Electricity Generation’ system is a technology which converts any kind of biomass energy with low heat value (such as waste from agriculture and forest and organic waste) into combustible gas and then feeds this gas to a generator for electricity generation.

Discovering the method of biomass gasification for electricity generation, can solve both problems of effective use of renewable energy and environmental pollution from organic waste. For this reason, the technology of biomass gasification for electricity generation attracts more and more research as well as applications. Thereby, this technology is being continuously optimised.

The model of biomass gasification for electricity generation can be realized as follows:

As shown, biomass gasification for electricity generation can be realized in 3 ways:

i. Fuel gas produced in a biomass gasifier enters directly into a boiler to produce steam, which then drives a steam turbine to generate electricity.

ii. The clean gas drives a gas turbine to generate electricity.

iii. The clean gas drives a gas engine to generate electricity.

Above pathways correspond to large-scale, medium-scale generation, respectively.

Today, commercially successful technologies for biomass generation using gas engines get wide application because of their small system capacity, nimble arrangement, low investment, compact structure, reliable technique, low running cost, simple operation and maintenance and their low demand for gas quality.

Main Composition of Biomass Gasification — Electricity Generation Systems Equipped with a Gas Engine:

The system is mainly composed of gasifier, gas cleaner and gas engine:

A gasifier is a system which converts solid biomass energy into combustible gas. Biomass is combusted imperfectly by way of controlling the flow of air into the gasifier to convert solid state into gas state, generating a combustible gas which mainly consists of H 2 , CO, CH 4 and C n H m .

The gas temperature in the outlet of the gasifier is in the range 350°C ~ 650°C, depending on the type of gasifier. The gas contains impurities such as dust and uncracked tar. In order to meet the demand of reliable gas engine operation over a long period of time, it is necessary to clean the gas at temperatures below 40°C as well as to reduce the content of dust plus tar below 50 mg/Nm. After cleaning, the gas is fed into the gas engine to generate electricity.

In the gas engine, the gas is mixed with air, burns and drives the main shaft to rotate at a high speed. The latter then drives the generator to generate electricity. Through above procedure, any waste can be converted into electrical energy, thereby solving pollution problems from wastes.

Biomass Gasification Electricity Generation Systems Equipped with a Gas Engine:

Specifications of the set contain power outputs of 60 kW, 160 kW, 200 kW, 400 kW, 600 kW, 800 kW and 1000 kW with the largest power output of about 1.4 MW. For power outputs below 200 kW, down-draft fixed bed gasifier are commonly used.

A typical down-draft fixed bed gasification set for the generation of electricity is shown in the following figure:

This down-draft fixed bed gasifier, can feed in raw material continually. The inlet of raw material is located at the top of the gasifier, raw material falls into the gasifier from the silo or it is transferred to the gasifier by a screw conveyer. In the lower part, the gasifer is equipped with a rotatory grid driven by a gearcase. The grid rotates continuously to extract ashes, the latter then being removed from the gasifier.

For cooling and cleaning of the gas use, a multistep water-washing is used. It is a reliable and cheap system meeting the demand of the engine. The gas engine is designed on the basis of the ‘6250 diesel engine’ so that it meets the low pressure ratio required by the produced bio-gas. In addition, a mixer structure outside of the machine and a simple reliable electric ignition system is used.

In case of electricity generation with larger capacity, fluidized bed gasifiers are used. As the greatest power output of a single gas engine is up to 200 kW, a fluidized bed gasifier is used to drive several gas engines at the same time.

A diagram of a fluidized bed gasification electricity generation system is shown below:

The gasifier uses a cyclical fluidized bed and it has high gasification efficiency and a powerful output. Raw material is formed grain or broken biomass and impurities such as ash or particles are removed from above by a cyclone.

The temperature at the outlet of the gasifier is about 600°C ~ 650°C. Removal of dust from the gas and gas cooling is realised by means of multistep water-washing. Several gas engines with an output of 200 kW generate electricity in parallel.

Applications of Gasifier:

Water Pumping and Electricity Generation:

Using biomass gas, it possible to operate a diesel engine on dual fuel mode-part diesel and part biomass gas. Diesel substitution of the order of 75 to 80% can be obtained at nominal loads. The mechanical energy thus derived can be used either for energizing a water pump set for irrigational purpose or for coupling with an alternator for electrical power generation – 3.5 kW -10 MW.

Heat Generation:

A few of the devices, to which gasifier could be retrofitted, are dryers for drying tea, flower, spices, kilns for baking tiles or potteries, furnaces for melting non-ferrous metals, boilers for process steam, etc.

Direct combustion of biomass has been recognized as an important route for generation of power by utilization of vast amounts of agricultural residues, agro-industrial residues and forest wastes. Gasifiers can be used for power generation and available up to a capacity 500 kW. The Government of India through MNES and IREDA is implementing power-generating system based on biomass combustion as well as biomass gasification.

(iv) Bio Fuels:

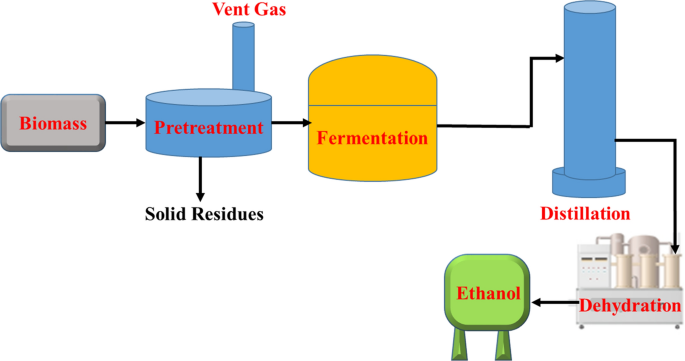

Unlike other renewable energy sources, biomass can be converted directly into liquid fuels — biofuels — for our transportation needs (cars, trucks, buses, airplanes and trains). The two most common types of biofuels are ethanol and biodiesel. See Fig. 1.51.

Ethanol is an alcohol, similar to that used in beer and wine. It is made by fermenting any biomass high in carbohydrates (starches, sugars or celluloses) through a process similar to brewing beer. Ethanol is mostly used as a fuel additive to cut down a vehicle’s carbon monoxide and other smog-causing emissions. Flexible-fuel vehicles, which run on mixtures of gasoline and up to 85% ethanol, are now available.

Biodiesel, produced by plants such as rapeseed (canola), sunflowers and soyabeans can be extracted and refined into fuel, which can be burned in diesel engines and buses. Biodiesel can also made by combining alcohol with vegetable oil, or recycled cooking greases. It can be used as an additive to reduce vehicles emissions (typically 20%) or in its pure form as a renewable alternative fuel for diesel engines.

Essay # 5. Environmental Impact Due to Biomass Energy Conversion:

Using biomass as a fuel produces air pollution in the form of carbon monoxide, NOx (nitrogen oxides). VOCs (volatile organic compounds), particulates and other pollutants, in some cases at levels above those from traditional fuel sources such as coal or natural gas. Black carbon – a pollutant created by incomplete combustion of fossil fuels, bio fuels and biomass – is possibly the second largest contributor to global warming.

On combustion, the carbon from biomass is released into the atmosphere as carbon dioxide (CO 2 ). The amount of carbon stored in dry wood is approximately 50% by weight. When from agricultural sources, plant matter used as a fuel can be replaced by planting for new growth. When the biomass is from forests, the time to recapture the carbon stored is generally longer and the carbon storage capacity of the forest may be reduced overall if destructive forestry techniques are employed.

Despite harvesting, biomass crops may sequester carbon. So for example soil organic carbon has been observed to be greater in switch-grass stands than in cultivated cropland soil, especially at depths below 12 inches.

The grass sequesters the carbon in its increased root biomass. Typically, perennial crops sequester much more carbon than annual crops due to much greater non-harvested living biomass, both living and dead, built up over years and much less soil disruption in cultivation.

Sustainability:

Biomass energy production involves annual harvests or periodic removals of crops, residues, trees or other resources from the land. These harvests and removals need to be at levels that are sustainable, i.e., ensure that current use does not deplete the land’s ability to meet future needs and also be done in ways that don’t degrade other important indicators of sustainability.

Because biomass markets may involve new or additional removals of residues, crops or trees, we should be careful to minimize impacts from whatever additional demands biomass growth or harvesting makes on the land.

Essay # 6. Benefits of Biomass:

When done well, biomass energy brings numerous environmental benefits—particularly reducing many kinds of air pollution and net carbon emissions. Biomass can be grown and harvested in ways that protect soil quality, avoid erosion and maintain wildlife habitat. However, the environmental benefits of biomass depend on developing beneficial biomass resources and avoiding harmful resources, which having policies that can distinguish between them.

In addition to its many environmental benefits, beneficial biomass offers economic and energy security benefits. By growing our fuels at home, we reduce the need to import fossil fuels from other states and nations and reduce our expenses and exposure to disruptions in that supply. Many states that import coal from other states or countries could instead use local biomass resources.

With increasing biomass development, farmers and forest owners gain valuable new markets for their crop residues, new energy crops and forest residues— and we could substantially reduce our global warming emissions.

Essay # 7. Scenario of Biomass Energy in India:

India being an agrarian country there is easy availability of agricultural based mass which can be used to generate energy. Burning the biomass is the easiest and oldest method of generating energy and also the least efficient.

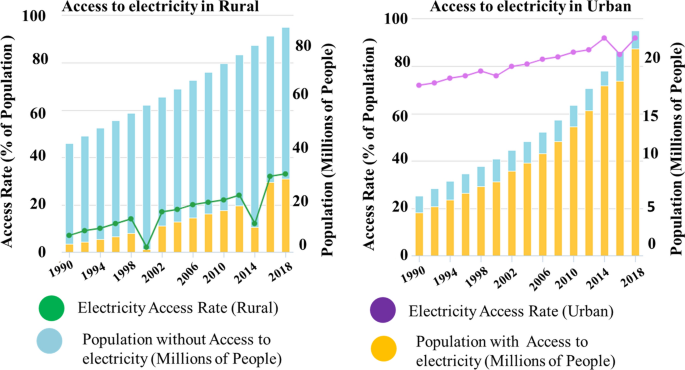

Over 70% of the population of India is in villages. Their electricity and steady supply of water are crucial for survival and for economic growth and social development.

Biomass exists in these villages and needs to be tapped intelligently to provide not only electricity but also water to irrigate and cultivate fields to further increase production of biomass (either as a main product or as a by-product), ensuring steady generation of electricity. An added bonus is the availability of waste biomass from the biomass gasified plant to be used as fertilizer.

Most common source of biomass is wood waste and agricultural wastes. In India development of biomass gasification has received serious attention with establishment of biomass research centers and gasifier action research centres at various locations spread all over the country.

These institutions have played a key role in up gradation and adaption of suitable technologies, testing, monitoring and development of biomass gasification systems. Studies reveal that the low grade of land suitable only for scrub vegetation can be turned to advantage and form an excellent source of biomass – fast growing trees and shrubs.

In India more than 2000 gasifiers are estimated to have been established with a capacity in excess of 22 MW and a number of villages have been electrified with biomass gasifier based generators. MNES has actively promoted research and development programmes for efficient utilization of biomass and agro-wastes and further efforts are on.

Biomass gasification offers immense scope and potential for:

i. Water pumping.

ii. Electricity generation: 3 to 1 MW power plants.

iii. Heat generation: for cooking gas – smokeless environment.

iv. Rural electrification means better healthcare, better education and improved quality of life.

Related Articles:

- Converting Biomass into Electricity: 5 Methods | Energy Management

- Energy Conservation in Agriculture Sector | Essay | India | Energy Management

- Essay on Solar Energy: Top 6 Essays | India | Energy Management

- Essay on Energy Scenario in India: Top 6 Essays | Energy Management

Bio Energy , Biomass , Energy Management , Essay , India

Privacy Overview

The Understand Energy Learning Hub is a cross-campus effort of the Precourt Institute for Energy .

Exploring Our Content

Fast Facts View our summary of key facts and information.

Before You Watch Our Lecture Maximize your learning experience by reviewing these carefully curated videos and readings we assign to our students.

Our Lecture Watch the Stanford course lecture.

Additional Resources Find out where to explore beyond our site.

Fast Facts About Energy from Biomass

Principal Energy Uses: Transportation, Electricity, Heat Form of Energy: Chemical

Biomass is a semi-renewable energy resource that comes from plants and animals. We categorize this resource as semi-renewable because it has to be carefully managed to ensure we are not using it faster than it can be replenished. Biomass contains stored chemical energy from the sun that is produced by plants through photosynthesis. Biomass can be burned directly for heat or converted to liquid and gaseous fuels through various processes. Liquid biofuels and biogas are energy carriers, or currencies, that are easier to use, transport, and store.

Humans have been using biomass for heating, cooking, and lighting, for thousands of years. About 30% of the world’s population (2.4 billion people) still use “traditional” biomass by gathering wood, peat, or animal waste to burn for cooking and heating. It is simple to store, but not very energy dense, and results in severe indoor air pollution with significant human health effects (3.2 million deaths in 2020). Traditional biomass provides ~7% of total end-use energy consumed worldwide. Energy statistics generally exclude traditional biomass , because it is not bought and sold, making it difficult to track.

In contrast, the International Energy Agency labels “modern bioenergy” as commercial biomass that provides heat and electricity in homes, businesses, and industry, as well as liquid fuels for transportation . Modern bioenergy accounts for ~6% of total end-use energy consumed worldwide .

Biomass can be divided into three categories:

- Solid Biomass (energy resource) —woody material, crops, municipal solid waste (MSW), and animal and agricultural waste that can be directly burned to produce heat or to generate electricity.

- Liquid Biofuels (energy currency) —primarily ethanol and biodiesel—come from processing plant matter or waste such as cooking oil into substitutes for traditional vehicle fuels, including gasoline for automobiles, diesel for trucks and ships, and jet fuel for planes (see our Gasoline, Diesel, Jet Fuel, etc. page for more information).

- Biogas (energy currency) — also known as biomethane—can be collected from decomposing plants, animal manure, human sewage, and municipal solid waste, and burned for heat and electricity generation.

Advocates for biomass argue it is carbon neutral because the carbon released during combustion was originally pulled from the atmosphere during photosynthesis, but the story is more complicated . Depending on the production process, some types of bioenergy increase greenhouse gas emissions, though using waste streams for bioenergy reduces climate and environmental impacts .

There are two main ways to use waste streams from municipalities (Municipal Solid Waste, MSW) for energy. Waste-to-energy incineration plants are the most common because of the amount of electricity they generate, their capacity to reduce the volume of waste, and lower capital investment, but they can have significant air pollution impacts. The second option is to capture the methane emissions from decomposing biomass in landfills or sewage treatment plants and burn that for heat and/or electricity generation. This cleaner-burning option reduces methane emissions to the atmosphere. Bioenergy from waste has had significant growth in Asia, especially in China, in the last decade.

Note: The data in the charts below does not include traditional biomass.

Modern Bioenergy

<2% of world 🌎 5% of US 🇺🇸

Solid Biomass Dominates Global Bioenergy Supply

Solid Biomass: 81% Liquid Biofuels: 14% Biogas: 5%

Uses of Bioenergy*

Heat: 71% Transportation: 18% Electricity: 9% of total global bioenergy

* Excluding conversion losses

Bioenergy Demand

Increase: ⬆ 23% (2015-2020)

Electricity Generation

2% of world 🌎 1% of US 🇺🇸

Transportation Energy

4% of world 🌎 6% of US 🇺🇸

Heat Generation

8% of world 🌎 8% of US 🇺🇸

Use of Bioenergy in Electricity

Denmark 17% 🇩🇰 Finland 15% 🇫🇮 of country’s electricity consumption

Use of Bioenergy in Transportation

Brazil 25% 🇧🇷 Sweden 21% 🇸🇪 of country’s total transport energy

Use of Bioenergy in Heat

Denmark 28% 🇩🇰 Sweden 25% 🇸🇪 of country’s heat consumption

Solid Biomass (Energy Resource)

80% of solid biomass is used for heat.

3% of global heat comes from solid biomass

20% of Solid Biomass Is Used for Electricity

2% of global electricity comes from solid biomass

Sources of solid biomass: natural woodlands, managed forests, fuelwood plantations

Liquid Biofuels (Energy Currency)

98% of liquid biofuels are used for transportation*.

4% of global transportation energy comes from liquid biofuels

* Almost all the biofuel use for transportation is for road transport. Biofuel use for air transport and shipping is small but expected to grow in decarbonization scenarios.

Biogas (Energy Currency)

91% of biogas is used for heat and electricity.

4% of global heat comes from biogas

<1% of global electricity comes from biogas

Note: 9% of biogas is upgraded to renewable natural gas (RNG). It can then be mixed into natural gas networks or directly used as a transport fuel.

Biomass (Primarily for Electricity and Heat)

Largest biomass electricity producer.

China 20% 🇨🇳 US 11% 🇺🇸 of global electricity generated from biomass and waste

Most Biomass Heat Generation

Europe 88% of total global biomass heat

Highest Penetration

Finland 14% 🇫🇮 of country’s total electricity consumption

Highest Usage of MSW

Japan 75% 🇯🇵 Denmark 67% 🇩🇰 of MSW incinerated for energy recovery

Biofuels (Primarily for Transportation)

Largest production capacity.

US 41% 🇺🇸 of total global refining capacity

Largest Consumer

US 40% 🇺🇸 of total global biofuels consumption

Brazil 25% 🇧🇷 Sweden 21% 🇸🇪 of country’s transportation energy comes from biofuels

Biogas (Primarily for Electricity and Heat)

Largest producer.

Europe 45% of total global biogas

Germany 35% 🇩🇪 of total global biogas-based electricity

Germany 6% 🇩🇪 of country’s electricity comes from biogas

Biomass in the US (for Electricity and Heat)

North Carolina 17% Georgia 15% of total biomass production capacity

Largest Consumers

Florida 9% California 9% of total biomass consumption

970,000 households in New England (17%) use wood for space heating

Vermont 17% of state’s electricity comes from biomass

The US dominates the wood pellet export market. In 2022, it exported 8.98 million metric tons (25% of total global wood pellet exports). Most exports go to Europe and come mainly from forests in the Southeast US. Eighty percent (10 million tons/year) of the US's wood pellet manufacturing capacity is in the South, mainly in North Carolina and Georgia.

Biofuels in the US (for Transportation)

Iowa 25% of biofuels produced in the US

California 11% Texas 11% of total biofuels consumed in the US

California 6% of transport fuel is biofuels

Biogas in the US (for Electricity and Heat)

Largest installed capacity.

California 17% of US biogas capacity

Massachusetts 27% of US biogas consumption for electricity

Rhode Island 2% of state’s electricity generation capacity is biogas

- Widely available resource in many settings

- Easy to store (particularly solid biomass and liquid biofuels)

- Taps waste as a fuel (e.g., landfill, forestry industry, sewage, etc.)

- Semi-renewable but must be carefully managed to ensure sustainability

- Diverse bioenergy resources, each with different characteristics

- Can replace fossil fuels, particularly for transportation and heat

- Useful byproducts, such as fertilizer

- Potential to be carbon neutral

- Potential competition with agricultural land and resources for food crops

- Planting single crops (monoculture) degrades soil and reduces biodiversity

- Use of pesticides and fertilizer harms water quality

- Can require lots of water usage

- Significant air pollution, except for biogas

- Net-carbon impact is unclear; some fuels are not carbon neutral

- Large land-use requirements that lead to deforestation

- Biomass-based power plants operate at a lower temperature than fossil fuel plants, which reduces efficiency

Climate Impact: Low to High

- Bioenergy crops have different energy yields, and some crops require significant energy inputs, reducing or eliminating their carbon savings

- Land use change such as deforestation or conversion of peat swamps to fuel crops releases carbon dioxide and methane

- Tapping waste streams for bioenergy can reduce these impacts

Environmental Impact: Medium to High

- Significant air pollution (e.g., vehicles burning biofuels deteriorate air quality and human health, particularly in urban settings)

- Bioenergy crop production may induce deforestation (e.g., in Southeast Asia, rainforests were converted to palm oil plantations to feed the EU’s demand for biodiesel)

- Agricultural processes can impact soil, water resources, and local biodiversity (e.g., increase in fertilizer use for corn ethanol has contributed to the dead zones in the Gulf of Mexico)

Updated December 2023

Before You Watch Our Lecture on Biomass

We assign videos and readings to our Stanford students as pre-work for each lecture to help contextualize the lecture content. We strongly encourage you to review the Essential videos and readings below before watching our lecture on Biomass . Include selections from the Optional and Useful list based on your interests and available time.

- Growing California Video Series: Cow Power . California Department of Food and Agriculture. March 13, 2015. (4 minutes) How one dairy is using an anaerobic digester to convert cow manure into methane gas to produce electricity.

- It’s Like We Don’t Matter: Green Energy Loophole Has Devastating Impact . CNN. July 7, 2021. (6 min) How the production of biomass for Europe is affecting poor rural communities in the American South.

- How Gasification Turns Waste Into Energy . CNBC. February 9, 2020. (16 min) An explanation of how gasification works and why it could be a better alternative than incineration.

- How Rotting Vegetables Make Electricity . World Wide Waste. March 6, 2021. (5 min) How the Bowenpally market in India converts unsold vegetables into biogas that powers buildings, streetlights, and a kitchen that serves 800 meals a day.

- The Smelly, Greasy Truth About How Sustainable Aviation Fuel Is Made . Canary Media. January 12, 2023. (3 pages) A truck driver dumpster-dives for used cooking oil in an effort to reduce emissions from commercial aviation.

- Biofuels Are Accelerating the Food Crisis — And the Climate Crisis, Too . Canary Media. April 19, 2022. (4 pages) An opinion piece that provides supporting evidence that land is better used to grow food than to grow fuel.

- Stop Trying to Make Algae Biofuels Happen . Canary Media. February 1, 2022. (2 pages) This article makes the argument that using algae to produce biofuels is unlikely to succeed.

Optional and Useful

- Biomass 2021 . NEED.org. 2023. (5 pages) An excellent overview of biomass.

- Europe’s Renewable Energy Policy Is Built on Burning American Trees . Vox. March 4, 2019. (7 pages) A good overview of the complexities of biomass as an energy source.

- Algae-Based Products for a Sustainable Future . Cellana. June 29, 2012. (2 minutes) A look at how Cellana uses marine microalgae to produce Omega-3 EPA and DHA oils, animal feed, and biofuel feedstocks.

- Renewables 2023 Global Status Report - Bioenergy . REN21. 2023. (6 pages) Market and industry trends for bioenergy.

- Biomass 101 . Student Energy. June 2015. (4 min) A simple and concise introduction to biomass.

- Mapped: 30 Years of Deforestation and Forest Growth, by Country . Visual Capitalist. December 29, 2021. (4 pages) Maps of deforestation and forest growth around the world.

- Whatever Happened to Advanced Biofuels? . Scientific American. May 2016. (3 pages) An explanation of the difficulties in producing ethanol from inedible crop waste.

Our Lecture on Biomass

This is our Stanford University Understand Energy course lecture on biomass. We strongly encourage you to watch the full lecture to understand biomass as an energy system and to be able to put this complex topic into context. For a complete learning experience, we also encourage you to watch / read the Essential videos and readings we assign to our students before watching the lecture.

Presented by: Diana Gragg, PhD ; Core Lecturer, Civil and Environmental Engineering, Stanford University; Explore Energy Managing Director, Precourt Institute for Energy Recorded on: May 22, 2023 Duration: 45 minutes

Table of Contents

(Clicking on a timestamp will take you to YouTube.) 00:00 Introduction 05:26 Significance and Use of Biomass 13:06 Commercial Biomass 44:44 Concluding Thoughts

Lecture slides available upon request .

Additional Resources About Biomass

Stanford university.

- Inês Azevedo - Transition to sustainable and low carbon energy systems

- Alfred Spormann - Bioenergy

- Reginald Mitchell - Combustion and gasification of pulverized coal and biomass

- Zhiyong Wang - Biomass

Government and International Organizations

- International Energy Agency (IEA) Bioenergy

- US Energy Information Administration (EIA) Biomass Explained

- US Energy Information Administration (EIA) Today in Energy Biomass

- US Environmental Protection Agency (EPA) Landfills

- US Bioenergy Technologies Office (BETO)

- National Renewable Energy Laboratory (NREL) Biomass Energy Basics

- California Energy Commission Biomass

Other Resources

- REN21 Renewables 2023 Global Status Report Bioenergy

- National Energy Education Development (NEED) Biomass

Next Topic: Hydropower Other Energy Topics to Explore

Fast Facts Sources Share of Global Population Without Access to Clean Cooking Fuels: 2020 ( SDG7 Database, IEA, March 30, 2022 ) Impacts on Health of Indoor Air Pollution: 2020 ( Household Air Pollution, WHO, November 28, 2022 ) Share of total global final energy demand: World 2020 ( Renewables 2023 Global Status Report, Figure 13, REN21, September 2023 ). Share of Energy Mix: World 2022 ( Global Primary Energy Consumption by Source, Our World in Data ), US 2022 ( US Primary Energy Consumption by Energy Source, 2022, US EIA ). Bioenergy Supply: World 2021 ( Bioenergy, IEA, Tracking Bionenergy. Energy ) Use of Bioenergy: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Renewable Energy ). Bioenergy Demand: World 2015-2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Renewable Energy ). Electricity Generation by Source: World 2020 ( Renewables 2023 Global Status Report, REN21,Bionergy ), U.S. 2022 ( Electricity in the United States, EIA, U.S. Electricity Generation by Major Energy Source 1950-202 2). Transportation Energy by Source: World 2020 ( Renewables 2023 Global Status Report, REN21,Bionergy ), U.S. 2022 ( Monthly Energy Review, EIA,Energy Consumption by Secto r). Heat Generation by Source: World 2020 ( Renewables 2023 Global Status Report, REN21,Bionergy ), U.S. 2022 ( Monthly Energy Review, EIA,Energy Consumption by Sector ). Use of Bioenergy in Electricity: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 11: evolution of renewable electricity output ). Use of Bioenergy in Transportation: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 17: evolution of the share of renewable energy in transport ). Use of Bioenergy in Heat: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 15: evolution of the share of renewable heat/fuels ). Solid Biomass Uses: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Renewable Energy ). Share of Heat Generated from Biomass: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Biomass to Heat ). Share of Electricity Generated From Biomass: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Biomass to Power ). Resources Used for Solid Biomass: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Biomass Supply ). Liquid Biofuels Uses: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Renewable Energy ). Share of Transport Energy from Biofuels: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Renewable Transport ). Resources Used for Liquid Biofuels: World 2021 (Is the biofuel industry approaching a feedstock crunch?, IEA,Total biofuel production by feedstock, main case, 2021-2027 ). Biogas Uses: World 2018 ( An introduction to biogas and biomethane, IEA, Biogas consumption by end use, 2018 ). Share of Heat Generated from Biogas: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Biomass to Heat ). Share of Electricity Generated From Biogas: World 2020 ( Global Bioenergy Statistics 2022, World Bioenergy Association, Biomass to Power ). Biogas Upgraded to Biomethane: World 2018 ( An introduction to biogas and biomethane, IEA, Biogas consumption by end use, 2018 ). Resources Used for Biogas: World 2018 ( An introduction to biogas and biomethane, IEA, Biogas production by region and by feedstock type, 2018 ). Highest Electricity Production from Biomass: World 2020 ( Electricity, EIA, Biomass and waste electricity net generation ). Highest Heat Generation from Biomass: World 2019 ( IEA Bioenergy Countries’ Report, IEA ). Highest Biomass Penetration: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 13: evolution of the share biobased electricity – split by fuel ), U.S. 2022 ( Electricity Historical State Data, EIA, Net Generation by State by Type of Producer by Energy Source ). Highest MSW Usage: World 2021 ( Municipal waste, Generation and Treatment, OECD ). Highest Biofuels Production: World 2021 ( Transport Biofuels, IEA, Biofuel Production 2010-2027 ), U.S. 2021 ( State Energy Data System (SEDS), EIA, Table P4B. Primary Energy Production Estimates, Biofuels, in Thousand Barrels, Ranked by State, 2021) . Highest Biofuels Consumption: World 2021 ( Transport Biofuels, IEA, Biofuel Production 2010-2027 ), U.S. 2021 ( State Energy Consumption Estimates 2021, EIA, Table C2. Energy Consumption Estimates for Selected Energy Sources in Physical Units, 2021 ). Highest Biofuels Penetration: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 17: evolution of the share of renewable energy in transport ), U.S. 2021 ( State Energy Consumption Estimates 2021, EIA ). Highest Biogas Production: World 2021 ( IEA Bioenergy Task 37 – A perspective on the state of the biogas industry from selected member countries, IEA ). Largest Biogas Production Capacity: U.S. 2022 ( LMOP Landfill and Project Database, EPA, Landfill Gas Energy Project Data ). Highest Biogas Consumption: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 8: evolution of biogas use for energy ), U.S. 2021 ( State Energy Consumption Estimates 2021, EIA ). Highest Biogas Penetration: World 2019 ( IEA Bioenergy Countries’ Report, IEA, Figure 13: evolution of the share biobased electricity – split by fuel ), U.S. 2022 ( LMOP Landfill and Project Database, EPA, Landfill Gas Energy Project Data ; Electricity Historical State Data, EIA, Existing Nameplate and Net Summer Capacity by Energy Source, Producer Type and State, 1990-2022 ). Largest Biomass Production Capacity: U.S. 2022 ( Monthly Densified Biomass Fuel Report, EIA, Table 1. Densified biomass fuel manufacturing facilities in the United States by state, region, and capacity ). Highest Biomass Consumption: U.S. 2021 ( State Energy Consumption Estimates 2021, EIA ). Highest Household Biomass Consumption for Heating: U.S. 2020 ( 2020 RECS Survey Data, EIA, Fuels used & end uses HC 1.7 and HC 1.8 ) Wood Pellet Production: U.S. 2022 ( Monthly Densified Biomass Fuel Report, EIA, Table 1. Densified biomass fuel manufacturing facilities in the United States by state, region, and capacity ). More details available on request . Back to Fast Facts

Biomass Energy

People have used biomass energy—energy from living things—since the earliest homonids first made wood fires for cooking or keeping warm. Today, biomass is used to fuel electric generators and other machinery.

Biology, Ecology, Earth Science, Engineering

Loading ...

People have used biomass energy —energy from living things—since the earliest hominids first made wood fires for cooking or keeping warm. Biomass is organic, meaning it is made of material that comes from living organisms, such as plants and animals. The most common biomass materials used for energy are plants, wood, and waste. These are called biomass feedstocks . Biomass energy can also be a nonrenewable energy source. Biomass contains energy first derived from the sun: Plants absorb the sun’s energy through photosynthesis , and convert carbon dioxide and water into nutrients (carbohydrates). The energy from these organisms can be transformed into usable energy through direct and indirect means. Biomass can be burned to create heat (direct), converted into electricity (direct), or processed into biofuel (indirect). Thermal Conversion Biomass can be burned by thermal conversion and used for energy. Thermal conversion involves heating the biomass feedstock in order to burn, dehydrate , or stabilize it. The most familiar biomass feedstocks for thermal conversion are raw materials such as municipal solid waste (MSW) and scraps from paper or lumber mills. Different types of energy are created through direct firing, co-firing , pyrolysis , gasification , and anaerobic decomposition . Before biomass can be burned, however, it must be dried. This chemical process is called torrefaction . During torrefaction, biomass is heated to about 200° to 320° Celsius (390° to 610° Fahrenheit). The biomass dries out so completely that it loses the ability to absorb moisture, or rot. It loses about 20 percent of its original mass, but retains 90 percent of its energy. The lost energy and mass can be used to fuel the torrefaction process. During torrefaction, biomass becomes a dry, blackened material. It is then compressed into briquettes . Biomass briquettes are very hydrophobic , meaning they repel water. This makes it possible to store them in moist areas. The briquettes have high energy density and are easy to burn during direct or co-firing. Direct Firing and Co-Firing Most briquettes are burned directly. The steam produced during the firing process powers a turbine , which turns a generator and produces electricity. This electricity can be used for manufacturing or to heat buildings. Biomass can also be co-fired, or burned with a fossil fuel . Biomass is most often co-fired in coal plants. Co-firing eliminates the need for new factories for processing biomass. Co-firing also eases the demand for coal. This reduces the amount of carbon dioxide and other greenhouse gases released by burning fossil fuels. Pyrolysis Pyrolysis is a related method of heating biomass. During pyrolysis, biomass is heated to 200° to 300° C (390° to 570° F) without the presence of oxygen. This keeps it from combusting and causes the biomass to be chemically altered. Pyrolysis produces a dark liquid called pyrolysis oil , a synthetic gas called syngas , and a solid residue called biochar . All of these components can be used for energy. Pyrolysis oil, sometimes called bio-oil or biocrude, is a type of tar . It can be combusted to generate electricity and is also used as a component in other fuels and plastics. Scientists and engineers are studying pyrolysis oil as a possible alternative to petroleum . Syngas can be converted into fuel (such as synthetic natural gas ). It can also be converted into methane and used as a replacement for natural gas. Biochar is a type of charcoal . Biochar is a carbon-rich solid that is particularly useful in agriculture . Biochar enriches soil and prevents it from leaching pesticides and other nutrients into runoff . Biochar is also an excellent carbon sink . Carbon sinks are reservoirs for carbon-containing chemicals, including greenhouse gases.

Gasification Biomass can also be directly converted to energy through gasification. During the gasification process, a biomass feedstock (usually MSW) is heated to more than 700° C (1,300° F) with a controlled amount of oxygen. The molecules break down, and produce syngas and slag . Syngas is a combination of hydrogen and carbon monoxide. During gasification, syngas is cleaned of sulfur, particulates, mercury, and other pollutants . The clean syngas can be combusted for heat or electricity, or processed into transportation biofuels, chemicals, and fertilizers . Slag forms as a glassy, molten liquid. It can be used to make shingles, cement, or asphalt. Industrial gasification plants are being built all over the world. Asia and Australia are constructing and operating the most plants, although one of the largest gasification plants in the world is currently under construction in Stockton-on-Tees, England. This plant will eventually be able to convert more than 350,000 tons of MSW into enough energy to power 50,000 homes. Anaerobic Decomposition Anaerobic decomposition is the process where microorganisms , usually bacteria , break down material in the absence of oxygen. Anaerobic decomposition is an important process in landfills , where biomass is crushed and compressed, creating an anaerobic (or oxygen-poor) environment. In an anaerobic environment, biomass decays and produces methane, which is a valuable energy source. This methane can replace fossil fuels. In addition to landfills, anaerobic decomposition can also be implemented on ranches and livestock farms. Manure and other animal waste can be converted to sustainably meet the energy needs of the farm. Biofuel Biomass is the only renewable energy source that can be converted into liquid biofuels such as ethanol and biodiesel . Biofuel is used to power vehicles, and is being produced by gasification in countries such as Sweden, Austria, and the United States. Ethanol is made by fermenting biomass that is high in carbohydrates, such as sugarcane, wheat, or corn. Biodiesel is made from combining ethanol with animal fat, recycled cooking fat, or vegetable oil. Biofuels do not operate as efficiently as gasoline. However, they can be blended with gasoline to efficiently power vehicles and machinery, and do not release the emissions associated with fossil fuels. Ethanol requires acres of farmland to grow biocrops (usually corn). About 1,515 liters (400 gallons) of ethanol is produced by an acre of corn. But this acreage is then unavailable for growing crops for food or other uses. Growing enough corn for ethanol also creates a strain on the environment because of the lack of variation in planting, and the high use of pesticides. Ethanol has become a popular substitute for wood in residential fireplaces. When it is burned, it gives off heat in the form of flames, and water vapor instead of smoke. Biochar Biochar, produced during pyrolysis, is valuable in agricultural and environmental use. When biomass rots or burns (naturally or by human activity), it releases high amounts of methane and carbon dioxide into the atmosphere . However, when biomass is charred, it sequesters , or stores, its carbon content. When biochar is added back to the soil, it can continue to absorb carbon and form large underground stores of sequestered carbon—carbon sinks—that can lead to negative carbon emissions and healthier soil. Biochar also helps enrich the soil. It is porous . When added back to the soil, biochar absorbs and retains water and nutrients.

Biochar is used in Brazil’s Amazon rainforest in a process called slash-and-char . Slash-and-char agriculture replaces slash-and-burn , which temporarily increases the soil nutrients but causes it to lose 97 percent of its carbon content. During slash-and-char, the charred plants (biochar) are returned to the soil, and the soil retains 50 percent of its carbon. This enhances the soil and leads to significantly higher plant growth. Black Liquor When wood is processed into paper, it produces a high-energy, toxic substance called black liquor. Until the 1930s, black liquor from paper mills was considered a waste product and dumped into nearby water sources. However, black liquor retains more than 50 percent of the wood’s biomass energy. With the invention of the recovery boiler in the 1930s, black liquor could be recycled and used to power the mill. In the United States, paper mills use nearly all their black liquor to run their mills, and the forest industry is one of the most energy-efficient in the nation as a result. More recently, Sweden has experimented in gasifying black liquor to produce syngas, which can then be used to generate electricity. Hydrogen Fuel Cells Biomass is rich in hydrogen, which can be chemically extracted and used to generate power and to fuel vehicles. Stationary fuel cells are used to generate electricity in remote locations, such as spacecraft and wilderness areas. Yosemite National Park in the U.S. state of California, for example, uses hydrogen fuel cells to provide electricity and hot water to its administration building. Hydrogen fuel cells may hold even more potential as an alternative energy source for vehicles. The U.S. Department of Energy estimates that biomass has the potential to produce 40 million tons of hydrogen per year. This would be enough to fuel 150 million vehicles. Currently, hydrogen fuel cells are used to power buses, forklifts, boats, and submarines, and are being tested on airplanes and other vehicles. However, there is a debate as to whether this technology will become sustainable or economically possible. The energy that it takes to isolate, compress, package, and transport the hydrogen does not leave a high quantity of energy for practical use. Biomass and the Environment Biomass is an integral part of Earth’s carbon cycle . The carbon cycle is the process by which carbon is exchanged between all layers of Earth: atmosphere, hydrosphere , biosphere , and lithosphere . The carbon cycle takes many forms. Carbon helps regulate the amount of sunlight that enters Earth’s atmosphere. It is exchanged through photosynthesis, decomposition, respiration, and human activity. Carbon that is absorbed by soil as an organism decomposes, for example, may be recycled as a plant releases carbon-based nutrients into the biosphere through photosynthesis. Under the right conditions, the decomposing organism may become peat , coal, or petroleum before being extracted through natural or human activity. Between periods of exchange, carbon is sequestered, or stored. The carbon in fossil fuels has been sequestered for millions of years. When fossil fuels are extracted and burned for energy, their sequestered carbon is released into the atmosphere. Fossil fuels do not reabsorb carbon. In contrast to fossil fuels, biomass comes from recently living organisms. The carbon in biomass can continue to be exchanged in the carbon cycle. In order to effectively allow Earth to continue the carbon cycle process, however, biomass materials such as plants and forests have to be sustainably farmed. It takes decades for trees and plants such as switchgrass to reabsorb and sequester carbon. Uprooting or disturbing the soil can be extremely disruptive to the process. A steady and varied supply of trees, crops, and other plants is vital for maintaining a healthy environment. Algal Fuel Algae is a unique organism that has enormous potential as a source of biomass energy. Algae, whose most familiar form is seaweed , produces energy through photosynthesis at a much quicker rate than any other biofuel feedstock—up to 30 times faster than food crops!

Algae can be grown in ocean water, so it does not deplete freshwater resources. It also does not require soil, and therefore does not reduce arable land that could potentially grow food crops. Although algae releases carbon dioxide when it is burned, it can be farmed and replenished as a living organism. As it is replenished, it releases oxygen, and absorbs pollutants and carbon emissions. Algae takes up much less space than other biofuel crops. The U.S. Department of Energy estimates that it would only take approximately 38,850 square kilometers (15,000 square miles, an area less than half the size of the U.S. state of Maine) to grow enough algae to replace all petroleum-fueled energy needs in the United States. Algae contains oils that can be converted to a biofuel. At the Aquaflow Bionomic Corporation in New Zealand, for example, algae is processed with heat and pressure. This creates a “ green crude ,” which has similar properties to crude oil, and can be used as a biofuel. Algae’s growth, photosynthesis, and energy production increases when carbon dioxide is bubbled through it. Algae is an excellent filter that absorbs carbon emissions. Bioenergy Ventures, a Scottish firm, has developed a system in which carbon emissions from a whiskey distillery are funneled to an algae pool. The algae flourishes with the additional carbon dioxide. When the algae die (after about a week) they are collected, and their lipids (oils) are converted into biofuel or fish food. Algae has enormous potential as an alternative energy source. However, processing it into usable forms is expensive. Although it is estimated to yield 10 to 100 times more fuel than other biofuel crops, in 2010 it cost $5,000 a ton. The cost will likely come down, but it is currently out of reach for most developing economies. People and Biomass Advantages Biomass is a clean, renewable energy source. Its initial energy comes from the sun, and plants or algae biomass can regrow in a relatively short amount of time. Trees, crops, and municipal solid waste are consistently available and can be managed sustainably. If trees and crops are sustainably farmed, they can offset carbon emissions when they absorb carbon dioxide through respiration. In some bioenergy processes, the amount of carbon that is reabsorbed even exceeds the carbon emissions that are released during fuel processing or usage. Many biomass feedstocks, such as switchgrass, can be harvested on marginal lands or pastures, where they do not compete with food crops. Unlike other renewable energy sources, such as wind or solar, biomass energy is stored within the organism, and can be harvested when it is needed. Disadvantages If biomass feedstocks are not replenished as quickly as they are used, they can become nonrenewable. A forest, for instance, can take hundreds of years to re-establish itself. This is still a much, much shorter time period than a fossil fuel such as peat. It can take 900 years for just a meter (three feet) of peat to replenish itself. Most biomass requires arable land to develop. This means that land used for biofuel crops such as corn and soybeans are unavailable to grow food or provide natural habitats. Forested areas that have matured for decades (so-called “ old-growth forests ”) are able to sequester more carbon than newly planted areas. Therefore, if forested areas are not sustainably cut, re-planted, and given time to grow and sequester carbon, the advantages of using the wood for fuel are not offset by the trees’ regrowth. Most biomass plants require fossil fuels to be economically efficient. An enormous plant under construction near Port Talbot, Wales, for instance, will require fossil fuels imported from North America, offsetting some of the sustainability of the enterprise . Biomass has a lower “energy density” than fossil fuels. As much as 50 percent of biomass is water, which is lost in the energy conversion process. Scientists and engineers estimate that it is not economically efficient to transport biomass more than 160 kilometers (100 miles) from where it is processed. However, converting biomass into pellets (as opposed to wood chips or larger briquettes) can increase the fuel’s energy density and make it more advantageous to ship. Burning biomass releases carbon monoxide, carbon dioxide, nitrogen oxides, and other pollutants and particulates. If these pollutants are not captured and recycled, burning biomass can create smog and even exceed the number of pollutants released by fossil fuels.

Balancing Biomass The Union of Concerned Scientists helped develop A Balanced Definition of Renewable Biomass, which are practical and effective sustainability provisions that can provide a measure of assurance that woody biomass harvests will be sustainable.

Fowl Play The three million chickens of the enormous Beijing Deqingyuan chicken farm, outside Beijing, China, produce 220 tons of manure and 170 tons of wastewater each day. Using gasification technology from GE Energy, the farm is able to convert chicken manure into 14,600 megawatt-hours of electricity per year.

Green Energy in the Green Mountain State The first U.S. biomass gasification plant opened near Burlington, Vermont, in 1998. The Joseph C. McNeil Generating Station uses wood from low-quality trees and harvest residue, and produces about 50 megawatts of electricityalmost enough to sustain Vermont's largest city.

World's Top Biofuel Crops ( HowStuffWorks ) 1. switchgrass 2. wheat 3. sunflower 4. cottonseed oil 5. soy 6. jatropha 7. palm oil 8. sugarcane 9. canola 10. corn

Articles & Profiles

Media credits.

The audio, illustrations, photos, and videos are credited beneath the media asset, except for promotional images, which generally link to another page that contains the media credit. The Rights Holder for media is the person or group credited.

Illustrator

Last updated.

October 19, 2023

User Permissions

For information on user permissions, please read our Terms of Service. If you have questions about how to cite anything on our website in your project or classroom presentation, please contact your teacher. They will best know the preferred format. When you reach out to them, you will need the page title, URL, and the date you accessed the resource.

If a media asset is downloadable, a download button appears in the corner of the media viewer. If no button appears, you cannot download or save the media.

Text on this page is printable and can be used according to our Terms of Service .

Interactives

Any interactives on this page can only be played while you are visiting our website. You cannot download interactives.

Related Resources

A review on biomass: importance, chemistry, classification, and conversion

Document Type : Review Paper

- Antonio Tursi

Department of Chemistry and Chemical Technologies, University of Calabria, Via P. Bucci, Cubo 15D, 87036 Arcavacata di Rende (Cs), Italy.

Graphical Abstract

- Overview of biomass sources and related chemical composition are presented.

- Biomass conversion technologies and final products are reviewed and discussed.

- Economic and environmental analysis of biomass-derived energy production was presented.

- Challenges for further expanssion of biomass-derived energy production are presented.

- Lignocelluloses

- Pretreatment

- Sustainability

Volume 6, Issue 2 - Serial Number 2 June 2019 Pages 962-979

- PDF 12.32 M

How to cite

- Article View: 22,492

- PDF Download: 24,342

Tursi, A. (2019). A review on biomass: importance, chemistry, classification, and conversion. Biofuel Research Journal , 6 (2), 962-979. doi: 10.18331/BRJ2019.6.2.3

Antonio Tursi. "A review on biomass: importance, chemistry, classification, and conversion". Biofuel Research Journal , 6, 2, 2019, 962-979. doi: 10.18331/BRJ2019.6.2.3

Tursi, A. (2019). 'A review on biomass: importance, chemistry, classification, and conversion', Biofuel Research Journal , 6(2), pp. 962-979. doi: 10.18331/BRJ2019.6.2.3

Tursi, A. A review on biomass: importance, chemistry, classification, and conversion. Biofuel Research Journal , 2019; 6(2): 962-979. doi: 10.18331/BRJ2019.6.2.3

- Reference Manager

- Simple TEXT file

People also looked at

Review article, an overview on the conversion of forest biomass into bioenergy.

- 1 Henan Province International Collaboration Lab of Forest Resources Utilization, School of Forestry, Henan Agricultural University, Zhengzhou, China

- 2 School of Psychology, Northeast Normal University, Changchun, China

- 3 Institute of Research and Development, Duy Tan University, Da Nang, Vietnam

- 4 Biofuel Research Team (BRTeam), Terengganu, Malaysia

- 5 Arctic Research Centre (ARC), Department of Bioscience, Aarhus University, Roskilde, Denmark

- 6 Higher Institution Centre of Excellence (HICoE), Institute of Tropical Aquaculture and Fisheries (AKUATROP), Universiti Malaysia Terengganu, Terengganu, Malaysia

- 7 Microbial Biotechnology Department, Agricultural Biotechnology Research Institute of Iran (ABRII), Agricultural Research, Education, and Extension Organization (AREEO), Karaj, Iran

Biomass plays a crucial role in mitigating the concerns associated with increasing fossil fuel combustion. Among various types of biomass, forest biomass has attracted considerable attention given its abundance and variations. In this work, an overview is presented on different pathways available to convert forest biomass into bioenergy. Direct use of forest biomass could reduce carbon dioxide emissions associated with conventional energy production systems. However, there are certain drawbacks to the direct use of forest biomass, such as low energy conversion rate and soot emissions and residues. Also, lack of continuous access to biomass is a severe concern in the long-term sustainability of direct electricity generation by forest biomass. To solve this problem, co-combustion with coal, as well as pelletizing of biomass, are recommended. The co-combustion of forest biomass and coal could reduce carbon monoxide, nitrogen oxides, and sulfide emissions of the process. Forest biomass can also be converted into various liquid and gaseous biofuels through biochemical and thermochemical processes, which are reviewed and discussed herein. Despite the favorable features of forest biomass conversion processes to bioenergy, their long-term sustainability should be more extensively scrutinized by future studies using advanced sustainability assessment tools such as life cycle assessment, exergy, etc.

Introduction

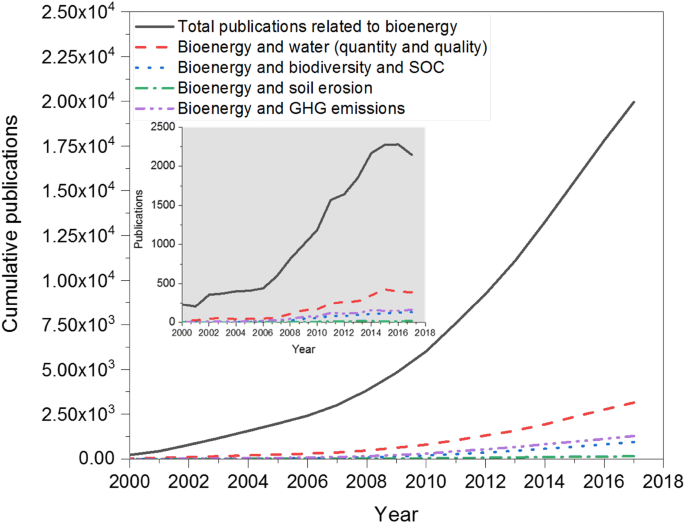

Greenhouse gases (GHGs) emissions and other harmful gases are among the primary global concern, mainly caused by the increasing use of fossil energy carriers ( Jun-jun and Da-rui, 2012 ). GHGs have been thought of as a critical factor in global warming that plays a crucial role in climate change ( Panahi et al., 2020b ). Extensive research has shown that using other carbon sources like biomass could reduce these concerns ( Hosseinzadeh-Bandbafha et al., 2018 ). In the literature available on the application of biomass to generate energy, the relative importance of forest biomass is debated ( Vassilev et al., 2010 ; Gustavsson et al., 2015 ). Generally, the forest biomass is classified into fuelwood and industrial roundwood ( Raunikar et al., 2010 ). Fuelwood is harvested from forestlands and directly combusted for useable heat or converted into bioenergy and biofuel and used to generate heat and power. More specifically, due to the high content of macromolecular sugars such as cellulose and organic matter, fuelwood is a promising feedstock for thermochemical conversion, biological conversion, liquefaction, and gasification ( Perez-Garcia et al., 2005 ; Tan et al., 2015 ). Forest biomass can be used in co-combustion with fossil fuels or alone in boilers and other equipment of power generation ( Scarlat et al., 2011 ; Calvo et al., 2013 ). Accordingly, when countries set their macro strategies related to energy development, efficient utilization of forest biomass resources to solve environmental crises is strongly considered ( Figure 1 ). For example, among the available energy sources in China, 54.2% of forest biomass is used to generate power and fuel ( Liao et al., 2004 ).

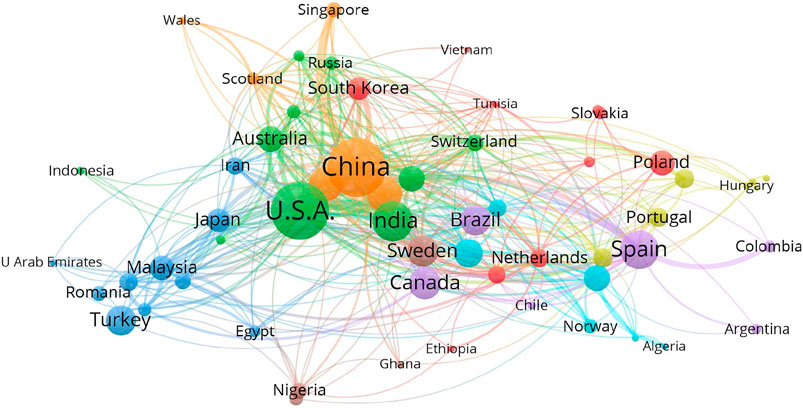

FIGURE 1 . Distribution of research activities on forest biomass to replace fossil-based energy carriers globally and the research interrelations between different countries.

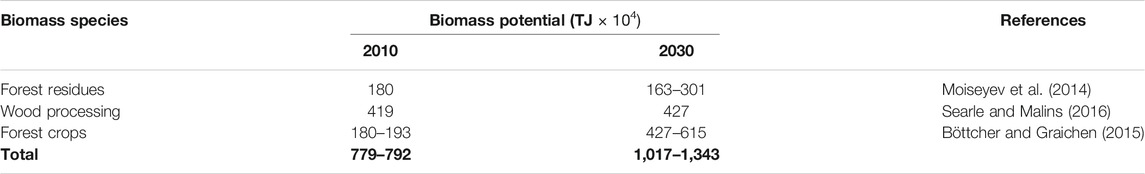

It is reported that the energy generated by forest biomass can support 15.4% of the total human energy consumption ( Welfle et al., 2014 ). During the period 2004–2015, the whole power generation from forest biomass stood at around one million kW/yr, contributing to the elimination of forest residues and achieving ecological-zero carbon dioxide (CO 2 ) emissions ( Ince et al., 2011 ; Nunes et al., 2018 ). For instance, forest biomass application as a replacement for fossil energy in Australia reduces atmospheric CO 2 emissions by 25 million tons annually ( Zomer et al., 2008 ; Pour et al., 2018 ). Furthermore, the European Union (EU) statistics show that there is an increasing trend for total energy that forest waste can provide for human consumption from 2010 to 2030 ( Table 1 ) ( Urban et al., 2010 ).

TABLE 1 . Statistics by the EU on energy generation from different types of forest biomass in 2010 and estimated values in 2030.

In light of the significance of forest biomass in the global energy market in the future, the present work aims to briefly report on various methods of forest biomass conversion into bioenergy and biofuels.

Direct Utilization of Forest Biomass

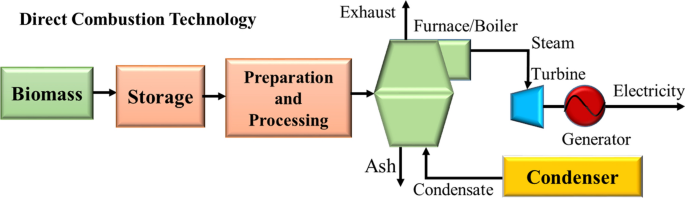

Direct combustion of wood for energy production.

A significant advantage of forest biomass is that it could be directly combusted. Direct combustion is a thermochemical process during which biomass burns in the open air, and the photosynthetically stored chemical energy of the biomass is converted into heat ( Lam et al., 2019 ). Although direct combustion of forest biomass leads to the emissions of CO 2 , particulates (PM 2.5 ), sulfur dioxide (SO 2 ), and other harmful substances, their amounts are still less than those caused by the combustion of fossil fuels ( Karaj et al., 2010 ; Kacprzak et al., 2016 ). For example, previous research has established that the direct combustion of forest biomass generates 20% less CO 2 emissions than fossil fuels ( Froese et al., 2010 ). However, there are certain drawbacks associated with the use of forest biomass. One of these is the low energy conversion rate; moreover, direct combustion leads to soot and residues ( Hong-ru and Yi-hu, 2007 ).

Direct combustion of biomass for power generation has continued since the 1990s ( Yin et al., 2008 ). Biomass-fired combined heat and power (CHP) plants include a vibrating grate boiler, condensing steam turbine, and electric generator ( Chen et al., 2021 ). The vibrating grate boiler is mechanized combustion equipment with a simple structure and small capacity. Its grate surface vibrates under the action of alternating inertial force and prompts biomass to leap forward on it to achieve mechanized combustion. Burning forest biomass produces heat within the boiler that converts water into steam (steam Rankine cycle). After water evaporation in the boiler, steam enters the turbine to expand and perform work, afterward pressure is reduced, and steam is condensed and converted to water ( Dote et al., 2001 ). It should be noted that the steam Rankine cycle is one of the most critical thermodynamic cycles for electricity generation ( Dincer and Bicer, 2020 ).

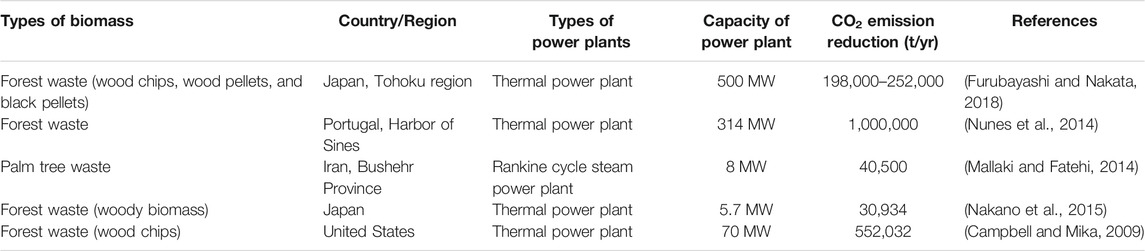

The conversion rate of forest biomass into electricity by Rankine cycle is reported at about 39–44%; therefore, the combustion of each ton of forest biomass generates about 4.4 kWh of electric energy ( Van den Broek et al., 1996 ; Dote et al., 2001 ). One obvious advantage of using this electric energy is reducing fossil-based CO 2 emissions caused by the power generation industry. Table 2 tabulates the CO 2 emission reductions of forest biomass-based power plants compared to their fossil-based counterparts.

TABLE 2 . CO 2 emission reduction potentials of biomass-based power plants compared to their fossil fuel-based counterparts.

A significant problem with the direct combustion of forest biomass for energy production is that these waste resources are generally far from industrial and residential areas. Moreover, the forests are vast, and biomass collation is a complex problem; thus, lack of permanent access to biomass is a severe concern in the sustainability of direct electricity generation using forest biomass. Nevertheless, it is recommended that forest biomass-based industries be located within a 120 km radius of forests to solve this concern. Still, they need a lot of financial investment and storage capacity ( Hoffmann et al., 2012 ).

Co-combustion of Forest Biomass and Coal

Co-combustion is a feasible and straightforward option for solving the concerns associated with the direct combustion of forest biomass, such as permanent access to biomass, the area required for storage, and economic problems related to transportation and distribution ( Liang et al., 2017 ). The main advantage of the mixed combustion of biomass and coal vs. coal combustion is that it could reduce carbon monoxide (CO), nitrogen oxides (NOx), and sulfide emissions while ensuring production efficiency ( Perea-Moreno et al., 2017 ). Technically, the co-combustion of forest biomass and coal uses pulverized coal boiler and fluidized bed boiler as the reactor. In the fluidized bed boiler, when forest biomass is added, the generation of nitric oxide (NO) is reduced, and the combustion process is more efficient ( Kabir and Kumar, 2012 ). Also, compared to coal, the volatile content of biomass is higher that is a favorable parameter for rapid ignition. It has been found that 87 tons of CO 2 emission could be reduced by replacing 1 ton of coal with forest biomass during co-combustion ( Royo et al., 2012 ). It is estimated that in 2030 and beyond, biomass utilization will increase by 450,000 t/yr, and relevant CO 2 emission reduction will reach 395,000 t/yr ( Kazagic et al., 2016 ). Furthermore, alkaline ash caused by biomass combustion can block SO 2 emissions from coal and reduce global acidification ( Demirba, 2005 ; Tsalidis et al., 2014 ).

Due to reducing harmful gases and increased power generation reliability, co-combustion is considered a cheap option to utilize existing biomass resources in power generation ( McIlveen-Wright et al., 2011 ). Given this fact, thermal power plants can use biomass as clean and cost-effective combustion supporting agent to mix with coal ( Dai et al., 2008 ). However, forest biomass suffers from several significant drawbacks despite these desirable features, e.g., poor energy density, high particle emissions, unstable combustion performance, and difficulties in storage and transportation ( Kang et al., 2018 ). Hence, future research should aim at providing solutions to mitigate these obstacles.

Forest Biomass Pellets

Several techniques have been developed to facilitate the transportation and improve the conversion rate of forest biomass, like mechanical processing of biomass into granular substance (pellet). Pelleting of forest biomass improves its density and reduces water content ( Valdés et al., 2018 ). Density and moisture are two critical properties of biomass affecting combustion efficiency. Hence, direct combustion or co-combustion of pelleted forest biomass with coal could increase combustion efficiency. For instance, it has been reported that the efficiency of pellet-fired boilers ranged between 85 and 90% compared with wood-fired boilers varying from 75 to 85% ( Sandro et al., 2019 ).

Forest biomass can also be mixed with other biomass to enhance the overall properties of the mixture for pellet production ( de Souza et al., 2020 ). For instance, the water content of biomass pellets could affect their durability, a property that could be adjusted by mixing different types of forest biomass. More specifically, when the moisture content of forest biomass is reduced to 1–5%, the average durability reaches 95%, which is convenient for the storage and transportation of the product ( Pradhan et al., 2018 ).

In the manufacturing process of forest biomass pellets, the biomass needs to be dehydrated in advance ( Civitarese et al., 2018 ). A rotary dryer could be used to remove the moisture in poplar wood chips, with a moisture removal rate of about 17%. In comparison, the moisture removal rate for Robinia pseudoacacia sawdust stands at a higher rate of 31%. These differences are ascribed to the differences in the density of various types of forest biomass ( Prokkola et al., 2014 ; Del Giudice et al., 2019 ). Notably, if the rotary dryer cannot remove the moisture effectively, the pneumatic dryer would be a good choice, also increasing the drying rate by 22% ( Frodeson et al., 2013 ).

From an environmental point of view, it is reported that if biomass pellets are used instead of coal for power generation, CO 2 emissions will be reduced by 205 Mt annually ( Purohit and Chaturvedi, 2018 ). Sikkema et al. (2011) reported that through the consumption of 8.2 million tons of wood pellets, 12.6 million tons of CO 2 emissions were avoided in all EU countries in 2008.